A dust management plan (DMP) is very specific to the industry and application. For example, a quarry’s needs may look vastly different from that of a building demolition site. First off, they produce a disproportionate volume of dust and often operate in contrasting environments (rural vs. urban). Each application produces varying types of dust and utilizes different methods of bulk material handling and equipment. A quarrying operation is fixed but expands and adjusts to changes in the environment, whereas a demolition contractor must adapt to several sites per year, each with unique needs and emissions.

As you can see, there is no one-size-fits-all approach to dust control. However, incorporating atomized mist technology into a dust management plan implemented by strategically placed dust control cannons and accessories has proven to be the most effective method to achieve compliant air quality and airborne particle suppression.

UNDERSTANDING YOUR ENVIRONMENT

We strongly encourage operators to first get a detailed environmental assessment from a reputable specialist. The environmental assessment will inform the dust control plan by first relaying what kind of hazardous substances the operation is/could be emitting, the regulations around this activity, and the potential impact on both staff and the surrounding ecosystem.

Although the environmental assessment might provide recommendations, it will likely not provide a comprehensive DMP. A dust management plan takes a deeper dive into specific permit requirements, seasonal weather patterns, particle sizes, causes of emissions, workplace safety, community safety, and specific dust-related environmental impacts.

The first step is understanding dust and emissions.

DUST SIZES AND THE SLIPSTREAM EFFECT

Dust particles or “Particulate Matter” (PM) are measured by diameter in microns (µm), which is a fancy word for micrometers (1,000,000th of a meter). Particles as large 200µm can remain suspended by normal ambient air currents. The smaller they get, the less visible they are to the naked eye, becoming barely visible at 100µm. At the size of <PM10 (the regulated size threshold for airborne crystalline silica particles), the dust is able to avoid the body’s natural defenses, penetrating deep into the lungs and causing chronic lung diseases. [Fig. 1]

Figure 1 - Dust size comparison.

(image courtesy of the EPA)

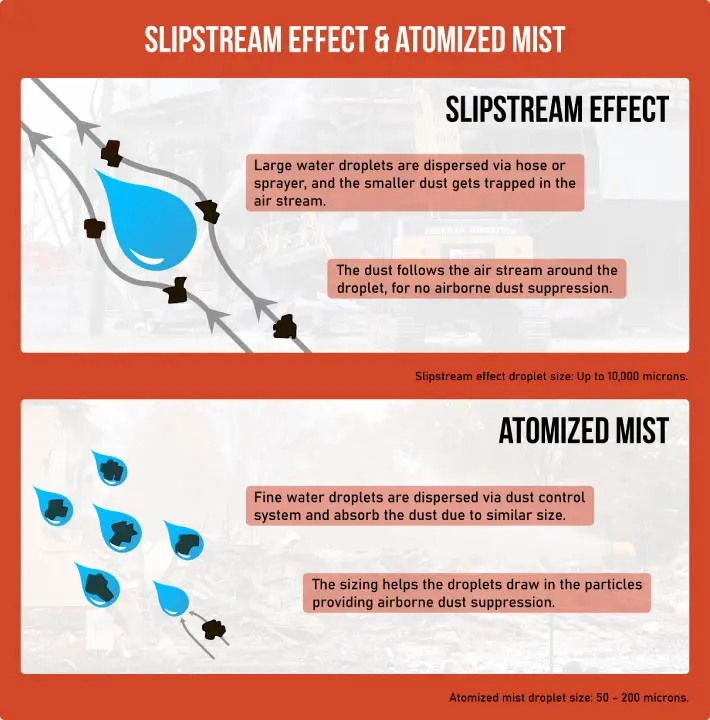

Airborne suppression of outdoor emissions is typically accomplished using water. Tests conducted over two decades reveal that droplets need to be approximately the same size as the airborne particulates to be effective. Hoses and sprinklers create droplets between 200µm and 1000µm, compared to atomized mist which is sized in the range of 15µm to 200µm. Droplet sizes greater than 200µm are only adequate for wetting surfaces, but don’t offer airborne dust suppression. This is due to the slipstream effect.

The mass of the falling droplet creates a swift air current that moves around it called a slipstream. Particles get caught in the slipstream and either move around the droplet, avoiding it altogether, or it could give the smallest particles lift, worsening the issue. In contrast, atomized droplets travel on air currents with the particles, absorbing them, and the collective mass drives both to the ground. [Fig. 2]

Figure 2: Slipstream effect.

What makes droplets from hoses and sprinklers so large? These methods depend on water pressure to propel the droplets long distances. A massive volume of water pushed through a narrow space is needed to propel the water and this volume creates larger droplets. An atomized misting cannon relies on a powerful fan to propel tiny droplets created by misting nozzles, using far less water and offering more complete coverage.

INDUSTRY CONSIDERATIONS FOR DUST MANAGEMENT PLANS

Formulating a dust management plan is wholly dependent on where the emissions are produced, the travel distance, and who/what is affected. The Occupational Safety and Health Administration (OSHA) is the regulatory body for workplace air quality and the safety of workers in the U.S. These regulations also extend to the Centers for Disease Control (CDC), which regulates from a health perspective (chronic lung diseases) and the Environmental Protection Agency, which looks at dust emissions as air pollution and regulates accordingly. Running afoul of any of these standards can result in violations, fines, and potential downtime.

Enclosed/Underground – The clean air intake system could be contaminated by tunneling and mining activities, so consider airflow and particle movement. Suppression of dust at the point of emission can mitigate airborne particulates using non-mechanical misting heads or DB-R misting rings that don’t violate restrictions on electrical or moving parts.

Enclosed and Naturally Ventilated – Manufacturing (wood products, aluminum casting, etc.), processing (recycling/MSW, crushing, sifting, etc.), and production plants (cement, fertilizer, etc.) generally depend on a system of open windows/doors and roof vents to pull heat and dust out. This category includes storage warehouses with massive tripper conveyors and reclaimers. However, this doesn’t control circulating dust within the enclosure, creating a workplace hazard. A compact cannon like the DustBoss DB-10 or the larger DB-30 help circulate the air, directing heat and airflow while suppressing airborne dust.

Bulk Handling and Storage – The use of tall stacker conveyors and storage areas is common for bulk handlers from ports to smelting to scrap yards. Tower-mounted DustBoss dust suppression cannons and DB-R misting rings are preferred for these applications to ensure complete coverage over tall storage piles and to control emissions from conveyor cargo discharged high in the air onto piles.

Open Operations – Even using natural barriers like trees and structures, open operations such as quarries, landfills, ports, and sowing of arid crops (grains, root veg, etc.) may require extensive wide area dust suppression with no runoff or pooling during operations. Larger dust cannons like the DustBoss DB-60 or DB-100 are designed for large, exposed areas. In regions with periodic high winds or applications in need of the reach of a pressurized stream, the DustBoss Surge is the ideal choice.

WHAT IS A DUST MANAGEMENT PLAN?

As we’ve shown, simply assigning a person to hose down dust-generating activities is not a plan. A DMP is a comprehensive document that states the causes, compliance requirements, testing measures, control methods, and policies for a specific operation. These standards are often set by government agencies such as the Mining Safety and Health Administration (MSHA) or a reputable trade organization like Conveyor Equipment Manufacturers Association (CEMA).

The dust management plan demonstrates to regulators that the operator has done their due diligence in good faith. It also provides resources -- both internal and contracted -- to inform, train, and track all operations that might affect air quality. The creation and administration of the DMP requires ongoing contributions from many stakeholders within the organization, but oversite largely falls on the Environmental Manager.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

THE RESPONSIBILITY OF OPERATORS AND ENVIRONMENTAL MANAGERS

Operators are responsible for ensuring that site environmental management requirements are met. In most cases, oversite will rest with the Environmental Manager (EM) to uphold the standards stated in the dust management plan.

Make sure staff and contracted personnel are trained on the DMP and are familiar with the procedures and their roles/responsibilities in dust prevention. Cutting corners or ignoring protocols shouldn’t be tolerated. The EM needs to ensure monitoring requirements are being met on all operations. It helps if contracted partners with large construction or operations projects appoint their own environmental representative to oversee that project. In some cases, monthly or quarterly reports are required on environmental impact, ensuring that independent auditors or inspectors appointed by the regulatory agencies (OSHA, CDC, EPA, etc.) are provided with detailed and up-to-date information.

SECTIONS OF A DUST MANAGEMENT PLAN

In the range of 10-50 pages long, depending on the size of the site and the scope of the project, the dust control plan is a report directed by an environmental specialist and maintained by internal resources. It is comprised of several different parts.[1]

- Summary – An overview of the goals, findings, and solutions. People should be able to get a good idea of what is in the report and get a positive impression that all parts are being proactively addressed.

- Acknowledgments – A list of contributors and external resources used to create the report.

- Contents – An index of the entire report with page numbers.

- Introduction – A narrative for the report from an environmental and workplace safety perspective. State the nature of the operations and the organization’s air quality goals. Highlight the collection of data and reasoning behind the chosen solutions.

- Project/Site Contacts – The names and contact information to whom regulators can direct questions.

- Project/Site Introduction –An introduction comprised of a short history, a description of the surrounding area, nearby communities, obstacles, and industrial activities around the site that may contribute to lower air quality.

- Environmental Evaluation – An examination of the existing air quality and contributing sources of particulate load on the air shed. It also covers several topics such as geology, soil quality, ecology, water quality, seismology, weather, and an environmental impact statement.

- Policy Evaluation - From an air quality standpoint, the DMP offers more detailed fugitive particulate data, regulatory policy, permit details, and assessment methodology than the environmental assessment.

- Dust Control Measures – A wide range of industries refer to the Hierarchy of Control Methods, which are listed from least effective to most effective, when determining what methods and measures to implement. The CDC defines Eliminate by Design as “removes the hazard at the source”, which is what DustBoss cannons are designed to accomplish by suppressing airborne particulates at the point of emission.[2]

- Monitoring – This section defines what is being tested, the testing methods, and frequency on a chart also showing ongoing testing results. It should, on a regular schedule (quarterly, bi-annually, or annually), provide insight into the effectiveness of the measures and offer recommendations.

- Conclusion – Closing thoughts and updated addendums.

- References – Any other links or source materials used to create the report.

- Glossary – A glossary of terms or abbreviations. Note that this can also be placed before or after the index.

DMP UPDATES AND CHANGES

Operations and attitudes toward air quality change as sites expand and communities grow around them. Operators should always keep the safety of staff and the surrounding community as their priority. However, companies also have an obligation to address the needs of customers and investors. Greater production demands can increase the volume of bulk material processed/handled and increase a site’s operating hours. The invariable result is a dramatic increase in the volume of dust. This will require significant changes to the DMP. Here are some things Environmental Managers should consider:

- Pinpoint the new dust‐emitting sources.

- Identify dust response triggers (wind, disruption, blasting, etc.).

- Define changes in the properties of emissions (size, hazard, etc.).

- Record the current and potential effects.

- Make a hypothesis on the impact.

- Implement PPE and administrative controls to mitigate the impact on staff during the evaluation period.

- Monitor the sources and the effects for a short period to test hypothesis.

- If dust control measures are in place in anticipation of the change, create a control test to monitor effectiveness.

- Create contingency plans for changes in weather conditions.

- Monitor sensitive receptors (ecological health, community health) when possible or partner with local groups to get updates.

Train staff on dust management and assign responsibilities for updating the plan.

CHOOSING THE CORRECT DUST CONTROL EQUIPMENT

Dust control methods can be an investment. Some methods such as hoses and sprinklers may seem like a low initial expense but end up costing more in labor and water usage. Here are some questions you may want to answer when choosing a dust control solution:

What is the required water source? Dust control solutions, for the most part, use water to suppress or control airborne emissions. Most DustBoss cannons can use city water with a standard 1.5 inch hose run through a booster pump to operate. If hydrant water is available, less pressure and volume is needed compared to standard hoses and sprinklers.

What is the required coverage area and can dust be controlled at the source? This determines the size and type of mist cannon needed. The best practice is to stop dust before it becomes airborne or close to the point of emission.

What is the power source? As we’ve show, solutions like hoses and sprinklers that use pressure instead of power are less effective against airborne dust. However, operations without a power source do have alternatives. The DustBoss Fusion is a self-contained unit powered by genset on a single roadworthy trailer.

What are the rules around standing water, pooling, and wastewater runoff for this site? The DustBoss family of cannons uses only 7-10% of the water volume of hoses, sprinklers and tanker trucks, saving hundreds of gallons of water per minute and thousands of dollars in water bills per annum.

How much labor and maintenance does the dust control solution require? Often, hoses, sprinklers and tanker trucks require labor to operate, adding to the cost. DustBoss units are autonomous. They are positioned, turned on, and left alone. Companies who bought DustBoss Systems often comment on the rugged construction and ease of use, as most models are accompanied by a Remote Control that can be operated from the cab of a vehicle or from a safe distance. Quality is why some of the first units sold decades ago are still in operation today.

CONCLUSION

Dust control plans take time and resources to create, but the cost of fines, negative public relations, and potential lawsuits is far pricier in the long run. Your BossTek representative can work with your team to show where and how you can integrate DustBoss technology into your operations to control airborne fugitive emissions and improve suppression. This insight will go a long way in producing a comprehensive dust management plan.

Contact Us and let our experience enhance your environmental goals, improve your community relations, and help you determine the best way to mitigate dust emissions to remain compliant.

CREATE A DUST MANAGEMENT PLAN TODAY!

Talk to a dust control specialist today to end fugitive dust!