Trying to stop dust from getting in the air is a valiant effort. Unfortunately, it's a hard fought battle. In most scenarios, dust is going to be generated and released into the air upon disruption. The demolition industry has copious amounts of dust created during the tear down of structures that preventive methods are not effective on, and many other industries suffer from potent, dust releasing activities.

Dust control at industrial and construction sites is essential to modern-day commercial operations. Luckily, there are plenty of innovative methods, some more effective than others, to stop the dust once it becomes airborne.

And no, a fire hose is not one of them.

3 WAYS TO REMOVE DUST FROM THE AIR

Misting Systems

Misting is the most effective way to stop dust in the air in terms of cost and efficiency. Using the optimum amount of water makes misting systems the ideal way to control airborne dust. Dust control solutions, like DustBoss cannons, use atomized mist to create fine water droplets in the 50 - 200 micron range. This range is the optimal size for water droplets to capture dust particles and drop them to the ground. If the size is too small, the droplet won't have enough weight on the dust particle to fall. If the size is too big, the slipstream effect comes into play, and the particle goes around the droplet in a stream of air. Not too big, not too small. Atomized mist is juuuust right.

Out of the gate, misting cannons may require an larger initial investment, but over time, the equipment can save more than the cost in water. Water is not free and using the optimum amount to precisely control dust can significantly reduce costs. When selecting misting equipment, choosing a product that is reliable and built to withstand the elements will provide the largest return. Cannons, like the DustBoss, require minimal maintenance and provide remote capabilities which reduce labor and operating expenses. Not to mention when comparing it to large-scale dust collection systems, misting cannons' initial cost is significantly lower.

Nozzle-Based Fogging Systems

Another solution to removing dust from the air is with nozzle-based fogging systems. These systems often use high-pressure pumps to direct water through stainless steel misting lines where nozzles convert and spray the water as fine droplets. These droplets act like misting cannons' atomized mist, capturing dust and dropping it to the ground while avoiding the slipstream effect. It also doesn't over-saturate the dust generating material due the small water droplet size. Compared to dust collection systems, nozzle-based fogging systems are significantly less expensive due to lower initial and operating costs.

These systems may have similarities to misting cannons in droplet size and saturation prevention, but the benefits of each varies. The leading difference between the two dust control systems is their ability to relocate. Nozzle-based fogging systems are permanent solutions for dust suppression using fixed metal piping to route water. Without any mobility, these systems are best suited for applications that have recurring dust in one central area like at conveyor discharge points. This permanence is represented in products' long-lasting warranties with some extending up to 30 years.

In contrast, misting cannons, like DustBoss units, are built with mobility and flexibility in mind. They offer horizontal oscillation, vertical adjustment and entire systems built for jobsite-to-jobsite transportation. These systems can take down dust in a center location, but with their mobility, they can stop dust in more active and variable situations like demolitions.

Another distinction of nozzle-based fogging systems is their customization. The piping is configured to meet individual's unique needs for dust control including how long/what shape the system needs to be, and how many nozzles need to be used to remove dust from the air. Dust control cannons don't currently offer this type of customization. Nozzle sizes, flow adjustment and accessories are available, but the cannons are mostly designed as a uniform product. Though many times, companies providing misting cannons work with customers to develop new solutions to meet their unique needs.

Though most misting systems are used in the form of large misting cannons backed by a powerful fan, smaller systems are available that function similarly to nozzle-based fogging systems. These small systems are fixed misters for more direct dust situations. Equipment like BossTek's DB-M Mini and DB-Ring are two pieces designed for no movement and use nozzles to provide dust suppression in a small, singular area. Areas such as conveyor discharge points are prime for smaller, direct dust suppression in substitute of nozzle-based fogging systems.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

DUST COLLECTION SYSTEMS

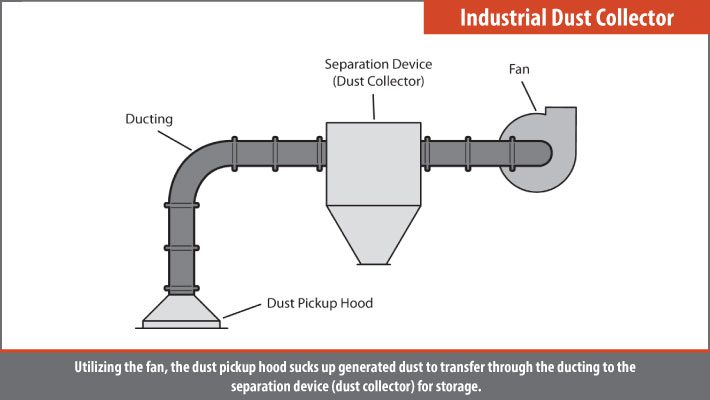

The most effective way to remove dust from the air in an indoor setting is with a dust collection system. These systems suck up the generated dust using a high powered fan and ducting to collect the unwanted particles in a separation device. The more the system is used, the more the particles it collects. Eventually, the device will need to be emptied, dumping the dust in another location.

Many see the continuous maintenance of dumping to be a hassle in removing dust from the air. The system may have successfully removed dust from the facility, but their dumping grounds may need misting or fogging systems to contain dust generated.

Another setback of industrial dust collectors is their expensive nature. Depending on the size of the operation, these systems can easily be more expensive than any fogging or misting equipment.

While misting and fogging cannons do drop dust, the use of water is often undesirable in a building or facility with too large of a throw. Industrial dust collectors don't have that issue, so if cost is not an issue, the collector will provide excellent indoor dust suppression.

There are various set-ups dust collection systems, but this is a common version of the system. Check out our detailed look at industrial dust collectors for more.

A smaller method of dust collection is exhibited using power tool vacuums to prevent dust from escaping into the air. These collection systems can be found on compact tools like partner saws and grinders. These are essential to help keep laborers safe when working directly with harmful substances. It is essential for activities like cutting into concrete with a partner saw to help avoid contact with silica dust.

REFERENCES

Modern Age of Dust Suppression - https://bosstek.com/modern-age-of-dust-suppression/

Industrial Dust Collector System Components - https://www.us-duct.com/special-duct-fabrications/industrial-dust-collection-systems

Dust Control - https://koolfog.com/dust-control/

READY TO REMOVE DUST FROM THE AIR AT YOUR JOB SITE?

Contact a dust control specialist today to remove fugitive dust!