Seeing dust particles floating in the air and settling -- perhaps even piling -- on work surfaces is a clear indicator of a potential workplace air quality violation. However, it would be misguided to just address the problem you can see when the respirable dust particulates you can’t see are the actual cause of the violation.

Plumes of dust result in complaints from neighbors and surrounding communities, and these complaints can trigger inspections from local authorities, the Occupational Safety and Health Administration (OSHA) and/or the Environmental Protection Agency (EPA). If emissions exceed regulatory standards either inside or outside (or both) of the operation’s site line, then inspectors can levy fines or temporarily shut down operations until violations are addressed. Often inspectors suggest remedies in reports and more and more they’re mentioning mist cannons as an effective dust management method.

To protect workers and avoid costly downtime, environmental engineers and risk management professionals recommend creating a Dust Management Plan to control dust at the point of emission. The plan identifies the causes of dust and times when emissions are most prevalent. Once these are recognized, the proper mist cannon and misting head can be used to best suppress dust particles before they travel.

DUST PARTICLE SIZING

Dust is Particulate Matter (PM) measured in microns (μm) which are one thousandth (10−3) of a millimeter or one millionth (10−6) of a meter. A dust particle size of 200μm is small enough to remain airborne, but once it reaches below 100μm, it becomes harder to see with the naked eye.

To find these tiny particulates, OSHA and EPA inspectors use gravimetric meters or personal dust monitors. Gravimetric meters are placed outside of the site upwind and downwind from the site line to measure the differences in dust levels entering and exiting the site. Personal dust monitors are worn by workers and test levels over an 8-hour shift.

TYPES OF DUST

Inhalable Dust Particles

There is a range depending on the individual, but in general, particulates above 50μm in size are considered inhalable and stopped from entering deep into the lungs by natural physical defenses such as hair and cilia. Although it may cause people to cough, get a scratchy throat, fill the nose and eyes with dust, and be overall unpleasant, the results are usually temporary.

Respirable Dust

A dust particulate size of 10μm or smaller is considered “respirable,” meaning it can bypass normal defenses to reach deep into the lungs, where it can accumulate and diminish breathing capacity. Long-term exposure can result in chronic obstructive pulmonary disease (COPD) and make people more susceptible to respiratory illnesses like pneumonia and bronchitis.

Respirable Crystalline Silica (RCS)

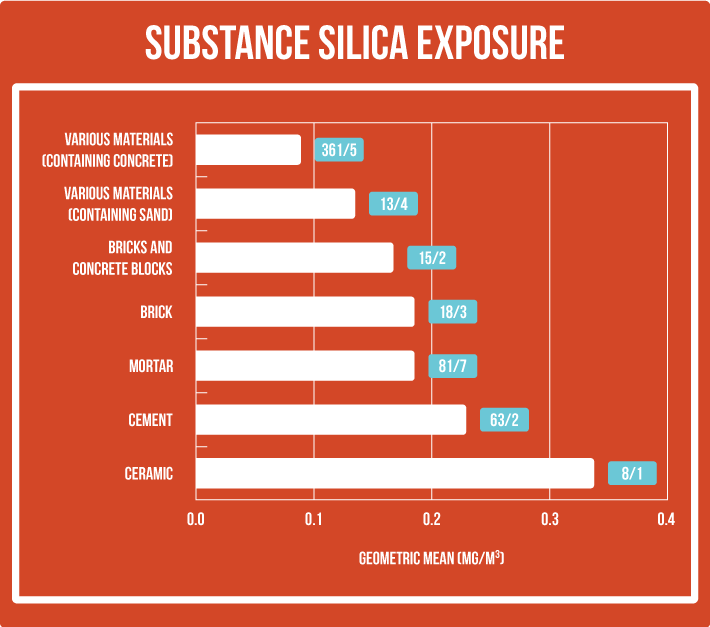

Regulators are most concerned over silica dust particles, because they drastically increase the mortality rate for workers across the bulk handling industries. Silicosis and pneumoconiosis (black lung) are variations of ailments caused by RCS exposure. The former is prominent in quarrying and cement production, and the latter is prevalent in underground mining, particularly coal mines. Measuring smaller than 10μm, silica dust particles are sharp crystalline formations that cause tiny tears in the lung tissue, leading to scarring in the lungs. Scar tissue restricts the lung’s ability to expand, slowly suffocating the patient over years.

OSHA AND EPA DUST REGULATIONS

Revised as recently as 2023, the OSHA Final Rule for RCS dust emissions in the bulk handling industries sets a personal exposure limit (PEL) of 10µg (stated as parts per million [ppm]) in a cubic meter (m3) over a time weighted average (TWA) of 8 hours.[1] The TWA compensates for workers moving in and out of different concentrations of RCS throughout a shift, but exposure over that period should be limited. Government regulators such as the EPA and the Mining Safety and Health Administration (MSHA) largely align with the OSHA rule, however, MSHA may have further restrictions due to a higher chance of a dust explosion.

LOCAL DUST ORDINANCES

In 2024, the City of Detroit, Michigan, levied its own ordinance regarding dust emissions with different criteria than OSHA and the EPA. Detroit’s air quality is among the worst of any city in the United States. Stakeholders cite the city’s industrial past and changes in the climate contributing to the rapid decline in air quality, resulting in Detroit having some of the highest rates of asthma in the country. One study found air quality issues caused nearly 1,500 annual hospitalizations and 660 premature deaths. The result has been a greater demand for air purifiers and higher costs for HVAC operation, as well as a greater burden on the medical care system, leading to medical costs above the national average. [2]

In response to demands from residents, the city council began investigating the air quality issue in 2022. Instead of emulating the measurement methods laid out by federal and state agencies, facilities like scrap yards and concrete plants are required to control visible airborne particles.

If city inspectors observe any visible dust moving beyond the premises of industrial businesses, they can issue violations and fines. Companies have two weeks to resolve a violation or face potential disruption to operations. The ordinance also requires facilities to create a fugitive dust plan outlining how it will control emissions. The plans must be approved by the Detroit Buildings, Safety Engineering, and Environmental Department (BSEED) before any new operations or construction starts.

This case study is important because some municipalities in the Southern United States such as Texas, Arizona, New Mexico, Utah and California implemented strict dust ordinances years ago. Rising scrutiny over dust emissions in a major northern city shows the shifting dynamic across the U.S. exacerbated by climate change.

Operators in all bulk handling, construction/demolition, waste/recycling and production sectors should proactively consider implementing a comprehensive dust management plan in a good-faith effort to avoid regulatory scrutiny. Mist cannons are an effective and highly visual representation of an operator’s commitment to dust control.

SUPPRESSING DUST: MIST CANNONS VS. HOSES

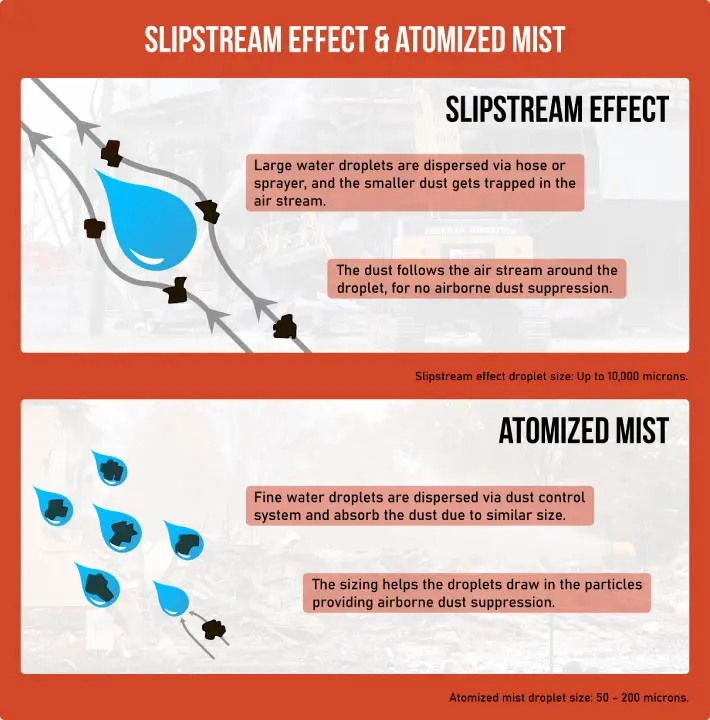

To successfully suppress airborne emissions, the mist droplets should be roughly the same size as the particulates they’re trying to capture. Although water remains the most common medium for control of airborne outdoor emissions, hoses and sprinklers create droplets between 200-1000µm in size. This is compared to atomized mist, which is in the range of 15-200µm. Droplet sizes greater than 200 µm are only adequate for wetting surfaces, but don’t offer airborne dust suppression. This is due to the slipstream effect.

As a large droplet moves through the air, the mass creates a strong current that moves around it called the slipstream effect. Particles get caught in the slipstream and remain uncontrolled. In some cases, the droplet can even lift the smallest particles, making the issue worse. Atomized droplets, on the other hand, travel with the particles, collide with them, and drag them to the ground.

To avoid the slipstream effect, dust suppression cannons distribute a fine engineered mist using a powerful fan-driven design or strategically placed misting bar/ring. Nucleating nozzles fracture pressurized water into millions of tiny droplets, preferably applied directly at the point of emission. Floating on atmospheric air currents with dust, tiny droplets also elevate the humidity of the target area, which helps capture particles and pulls them to the ground before they travel. Settling droplets provide surface suppression evenly across the material using less water than hoses and sprinklers, drastically lowering the volume of runoff and reducing the chance of pooling.

DUST CONTROL SOLUTIONS

To distribute atomized mist, there are electric options and non-electric options, however, to distribute atomized mist over a wide area, electricity is required. Mist cannons use a high-powered fan at the back of a cone-shaped barrel. As the fan forces air through the cannon, a ring manifold with multiple nozzles mounted on the front (exit side) of the barrel fractures pressurized water into atomized droplets. When the force of air hits the mist, millions of minuscule droplets are propelled into the air in a cone-shaped pattern.

Similar to the misting ring on the cannon, the non-electric misting heads and rings use water pressure to fracture the water with similar nozzles and spray the fine mist with precision in a limited space. However, without the aid of a fan, the mist descends quickly, making it excellent for localized dust control.

Misting Heads are highly effective at controlled throughput points such as the mouths of hoppers/bins, conveyor transfer points, and shaker screens. A dosing system that introduces chemical surfactants can be added to reduce dust from hydrophobic substances like coal.

Misting Rings are most utilized at conveyor discharge points where material leaves the belt in an unaided descent exposed to wind, such as from a stacker conveyor. The stainless-steel ring surrounds the material stream with a curtain of light mist that falls with the material, preventing fugitive emissions from escaping.

Compact mist cannons (DB-10, DB-Atom) have two-wheel carriages with a handle and are roughly the same size as a large snow blower. Their versatility makes them excellent for both indoor and outdoor applications. They’re easy to maneuver, while still offering industrial dust control over a localized area.

Mid-sized Cannons (DB-30, DB-45 Surge) are mounted on mobile carriages or skids which are easily moved by small equipment or a pickup truck. The “Fusion” version is equipped with a power generator. They have a reach of up to 100 ft (30 m) and a coverage area of up to 2,880 m2 (31,000 sq ft) when equipped with oscillation.

Large Misting Cannons (DB-60, DB-100) are also mounted on roadworthy mobile carriages and are available in a Fusion version. Optimal for large worksites with multiple sources of fugitive dust, they have up to a 328 ft (100 m) throw distance and cover as much as 280,000 square feet (31,000 square meters) when oscillating.

DUST CONTROL INNOVATIONS

Industries like demolition and quarrying require dust control technology to be versatile in windy conditions to reach elevated places where hydraulic claws and blasting may create emissions that can travel high into the air. Not limited to just those industries, most outdoor applications – even those with wind barriers – experience windy conditions that can disrupt the effectiveness of atomized mist. That’s why BossTek designed the DustBoss® Surge®.

This mid-sized cannon can be operated in three stages by using a combination of the 25-horsepower industrial fan, misting ring and the innovative central high-pressure jet-to-plume (J2P) spray nozzle. The pressurized spray resists wind shear, using the wind’s force to fragment droplets to the dust particle size threshold, thus enhancing its dust suppression capabilities.

The three stages are easily controlled by the touch screen system or by the hand-held remote. Stage 1 uses the powerful fan and misting ring for wide area coverage. For moderately windy days, stage 2 features a pressurized stream delivered by the J2P nozzle to pinpoint the source of the dust. On high wind days, operators can choose stage three which utilizes the fan, misting ring and center nozzle for maximum coverage.

DUST PARTICLES

Operators generally seek ways to protect workers out of care and respect for their staff. Sometimes dust can be overlooked, especially if the particles can’t be seen. By assessing dust sources and creating a mitigation plan, managers can improve workplace safety, increase employee morale, and maintain better relations with the local community and municipal leadership.

DustBoss cannons are a field-proven, inspector-approved method of controlling airborne dust and engaging in preventive surface suppression. They’re also a visual representation of an operator’s care for employees and the community, with units available for both purchase and rental. BossTek specialists have years of experience in effectively implementing mist cannon technology to control dust particle emissions and can walk you through your dust management plan.

READY TO FIGHT AGAINST DUST PARTICLES?

Contact BossTek® today to speak with a dust control specialist and improve air quality!