Many people don’t realize that asbestos is a naturally occurring mineral that has been mined and applied for different uses by humans for several millennia. With tough fibers, items containing asbestos were found to be resistant to heat, electricity, and corrosion. In Northern Europe, clay pots dating back to 2500 BC contained asbestos to strengthen them and it was used to preserve the bodies of ancient Egyptian pharaohs. The asbestos that we know today began with the H.W. Johns Manufacturing Company in 1858, manufacturing fireproof roofing material. Ironically, Henry Ward Johns died from asbestos dust exposure forty years after its founding.

Only used now for approved and regulated products and processes, before the restrictions were enacted in the ‘70s, it could be found in nearly every construction product and vehicle in America. The sheer volume of asbestos products used in construction was demonstrated after the fall of the World Trade Center Twin Towers in New York City following the 9/11 terrorist attack when an estimated 1000 tons of dust fibers were spread widely across the city. However, asbestos is still in demand in the U.S., in fact, over 110 tons (100 tonnes) of the processed substance is imported every year despite being completely banned in Canada, much of Central and South America, and Europe.

Nearly all products containing asbestos available to the public in the U.S. are strictly regulated and cannot have the chance for emission. Able to shed as light weight abrasive fibers, the airborne dust from asbestos has been categorized as a toxic substance by the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and the Centers for Disease Control (CDC). Thus, the detection of it in a building prompts expensive and well-regulated abatement during removal and demolition requiring personal protective equipment (PPE) such as respirators. Another prevalent place asbestos is found is in quarrying operations, where commonly mined minerals can create dust.

To control the asbestos dust at the point of emission, operators in both the demolition and quarrying sectors have added atomized mist cannon technology to the process. The mist created by these units has been field tested and proven to be highly effective in capturing airborne asbestos dust particles.

HEALTH RISKS OF ASBESTOS

The health hazards of asbestos are well-documented, but there are still around 3000 asbestos-connected deaths per year in the U.S. Prolonged exposure has been linked to lung cancer, asbestosis, and mesothelioma. When inhaled, microscopic fibers become lodged in the lungs and as the body's immune system attempts to remove them, the tissue of the lungs becomes scarred over time, weakening lung tissue. This also results in the stiffening of the lungs, making it more difficult for them to fill with air and provide oxygen to the body. Asbestos-related diseases can have a dormancy period of 10 to 50 years, with symptoms presenting themselves 20 to 30 years after exposure; by this time, the disease is almost full-blown with fatal consequences.

CONTROLLING ASBESTOS DUST ON WORK SITES

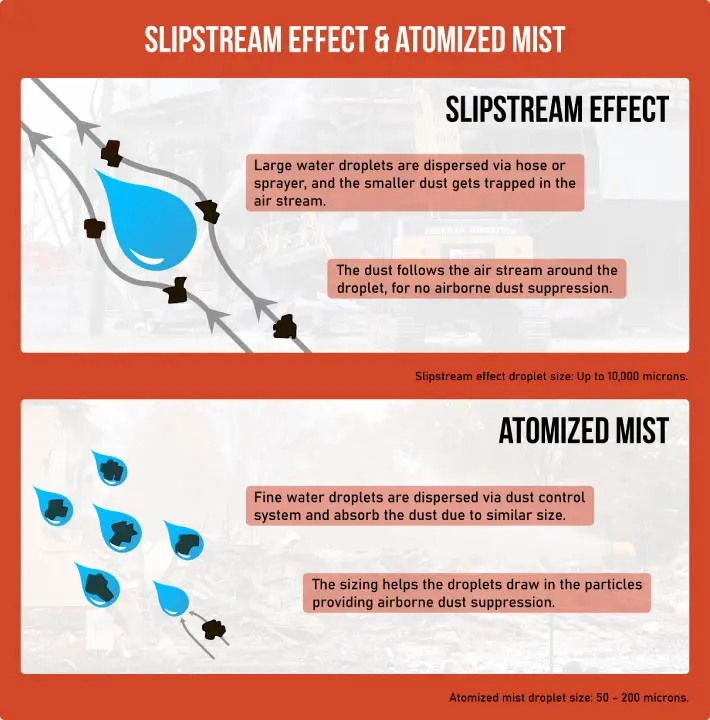

Protecting workers and the public from asbestos dust includes using PPE, sealing the area with plastic sheeting, and wetting the site with water hoses. The most effective strategy for industrial purposes is using atomized mist, which aims at controlling particulate emissions before they become airborne. The reason is, unlike water hoses with large droplet sizes that create a slipstream around the droplet, the size of an atomized mist droplet is small enough to travel with asbestos particles, collide with them, and use their collective mass to pull them to the ground.

Dust size is measured by diameter in micrometers or microns (µm) and volume in micrograms (µg) using personal detection devices. Light weight Particulate Matter (PM) as large as 200µm can remain airborne on ambient air currents and becomes no longer visible to the naked eye under 100µm. Asbestos fiber strands can be the microscopic size of <PM10, meaning the particles avoid the body’s natural defenses and penetrate deep into the lungs.

Water remains the sole medium for controlling airborne emissions. Field tests have shown that droplets should be approximately the same size as the particles to effectively suppress airborne particulates. Hoses create droplets between 200µm and 1000µm compared to atomized mist, which is sized in the range of 15-200µm. Droplet sizes greater than 200µm are only adequate for wetting surfaces, but don’t offer airborne dust suppression. This is due to the slipstream effect. As a droplet moves through the air, the mass creates a strong current that moves around it called a slipstream. Particles caught in the slipstream avoid the droplet and in some cases are even lifted by it.

To create droplets small enough to capture airborne dust, specialized atomizer nozzles fracture pressurized water and distribute it evenly across the source of the dust emissions. The droplets raise the humidity of the treated area, floating on atmospheric air currents with the dust, colliding with it. Settling droplets provide surface suppression evenly across the material using less water, lowering the volume of runoff and reducing the chance of pooling. Air cannons distribute the droplets in two ways, either strictly using water pressure or with a powerful fan contained in an engineered barrel.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

ASBESTOS DUST IN DEMOLITION

Asbestos dust emissions during demolition are released into the air when disrupting or moving materials containing asbestos, such as insulation, roofing materials or floor tiles. Also, striking, cutting, drilling, sweeping, dusting or unfiltered vacuuming of settled dust are other ways that asbestos dust can become suspended in the air.

Specific steps are taken to check the spread of asbestos on demolition sites. First, all staff must wear PPE -- suits, respirators and eye protection -- within the hazardous zone, and areas with the highest exposure to dust should be properly sealed. Although workers are protected by PPE, dust particulates in sealed environments often clog air intakes of the machinery performing the demolition, requiring downtime for maintenance several times during a single shift. Air filters and industrial vacuum motors may also require diligent maintenance, extending the timeline of the project.

To help prevent volumes of dust in enclosed areas from overpowering PPE or machinery, smaller mist cannons control dust at the point of emission. They produce industrial dust control results without the excessive pooling or runoff associated with hoses.

The compact dust solution DustBoss® DB-10 is designed for enclosed or confined working environments. About the size of a large baby stroller, it can easily be maneuvered throughout the site in minutes by hand by one person. Fully autonomous, the worker merely attaches the water hose and power cord, points it at the working face, adjusts the vertical throw angle, turns it on, and walks away.

Designed for indoor demolition, it has a single-phase, 120V electric motor powering a fan with a 30 ft (10 m) throw distance with minimal water usage of only 0.35 gpm. With an adjustable throw angle of 0° - 50°, it can reach most ceilings and suppress dust from above. The result is an effective airborne particle control with less standing water than hoses and a safer, more compliant workplace.

For indoor operations with higher ceilings, a wider working area, and limited access to a power source, the DustBoss Atom® uses pressurized water from a pump powered by a 9.1 HP air-cooled Tier IV diesel engine rather than a fan. With a throw distance of 30 meters (~100 feet) and the unit’s 0-65º vertical adjustment, operators can direct the spray at a specific area or use the 100º oscillation range to cover a wide 567 sq/m (6,100 sq/ft) area.

Although slightly heavier than the DB-10, the Atom is still designed to be easily lifted, maneuvered, and controlled by a single worker. Once the worker has pointed it toward the work face, it has the added benefit of only requiring a water connection. The concentrated pressurized stream and oscillation makes it more versatile for windy conditions and the heavy-duty remote control allows operators of equipment to direct dust suppression as they maneuver without leaving the cab.

ASBESTOS DUST AT QUARRIES

Quarries extract several minerals that can contain asbestos fibers. Limestone, for example, is a commonly quarried substance containing asbestos. Activities that cause dust include blasting and cutting stones, ripping, digging or excavating, crushing, screening and grinding. However, beyond extraction and processing, further operations like conveying, stockpiling and transporting can spread dust.

A popular model used by quarries for its versatility and mobility is the DustBoss DB-60 Surge®. Quarry operators like how it is mounted on a road-worthy carriage or liftable skid, making it easily transported and set by a pickup truck or skid steer. The versatility comes when operators can shift between wide area atomized mist coverage -- excellent for suppressing large plumes of drifting dust from blasting -- to nearly surgical precision at workfaces that require pressurized wetting.

The Surge has a heavy-duty barrel with a powerful industrial fan in back, misting ring in front and a central high-pressure spray nozzle with the reach and force of a hose. Controlled by a 3-stage system that can be adjusted by a hand-held remote, the first stage is highly effective on moderate days for airborne and surface coverage. It uses the powerful 25 HP / 30,000 CFM (849.5 CMM) fan and misting ring to deliver fine atomized mist over a wide area. For windy days, stage two features a pressurized stream delivered by the central nozzle. On high wind days, operators can utilize the fan, misting ring and center nozzle for maximum coverage.

The pressurized spray resists wind shear and even uses the force of the wind to further fragment and carry the droplets, enhancing its dust suppression capabilities. Fed by a standard 1-½ in. (38 mm) hose with a cam-and-groove quick disconnect coupling, the powerful booster pump delivers as much as 500 PSI (27.5 BAR) of water pressure to the center nozzle, with an output of only 37-100 GPM (140-378 lpm).

ASBESTOS DUST CONTROL

Asbestos stays in the body and only decades later manifests as a chronic lung condition. For ancient people who didn’t live past 45 years old, this may not have been an issue, but in modern society, regulators are fully aware of the health consequences.

The DustBoss Atom, DB-10 and DB-60 Surge are ideal for indoor demolition projects and outdoor quarry operations. Using BossTek's range of atomized mist cannons will subdue asbestos dust before it becomes airborne, making the worksite a safer, healthier and more compliant place for everyone.

To know more about how we can help with your construction, demolition and quarrying projects, do contact us.

PREVENT ASBESTOS EXPOSURE WITH DUST CONTROL TODAY!

Receive a FREE quote and talk to a dust control specialist today to end asbestos dust!