d

WHY CONVENTIONAL SPRAYING DOESN'T WORK FOR SILICA DUST

OSHA's final rule for outdoor dust suppression is unfortunately incomplete and potentially expensive. The rule states that material-handling workers need to frequently pause from their work to lightly spray water over storage piles and raw-materials receiving areas for dust control, most likely using a hose.

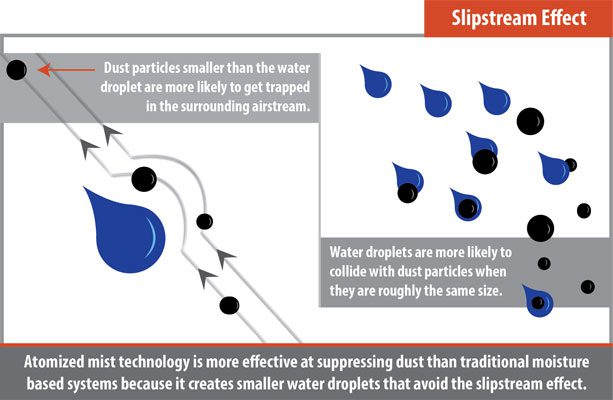

Here's the problem: Sprayers (including hoses, sprinklers, water trucks, etc.) create droplets that are too large to offer actual dust suppression, due to the extremely small size of silica dust particles. It's an issue called the Slipstream Effect.

The Slipstream Effect

When a water droplet is sprayed into the air, its size and velocity cause air to rapidly flow around it, much like air flowing around an airplane's wing.

Though small, the airflow around a falling droplet (200µm 10 1000µm in size) is actually strong enough to deflect and even lift a dust particle. That means the water sprayed from a conventional hose or water truck enables dust to literally "dance through the raindrops" and to avoid suppression.

Trapping Silica Dust with Atomized Mist

A better approach is atomized mist droplets - ranging between 50 and 200 microns in size. These tiny drops of water linger in the air and create very little slipstream.

In fact, they collide with airborne dust particles and then drive them to the ground and seal them there. It's one of the few technologies that helps create safe and more compliant work sites by managing both airborne particle control and ground-level dust suppression.

When used in tandem with a surfactant and dosing pump, the atomized mist technology is effective on an extremely wide range of applications and materials. The mist from a single machine can cover up to 280,000 sq ft (26,000 sq ft), while also minimizing water consumption by using less than 39 GPM (147.6 lpm).

Atomized mist creates a wide area of airborne and surface dust control at the point of emission.