Environmental and community safety concerns are top of mind for decision-makers when choosing a demolition contractor. Demolition company owners have said that owning an industrial fog/mist cannon as part of their core offering has made them stand out from the competition and contributed significantly to capturing new, more lucrative projects.

Demolition is a dusty business. Staff can hose down concrete supports, brick walls, etc. with water, but once heavy equipment hits them, airborne dust plumes are released that can travel for miles. The same goes for moving, separating, and storing the material. Even when the surface is wet, disruption can discharge large volumes of dust as front loaders engage in construction and demolition (C&D) material recycling and waste management, dubbed by the EPA as sustainable materials management (SMM). If a SMM plan does not comply with EPA air quality standards, then one could argue that it’s far from “sustainable.”

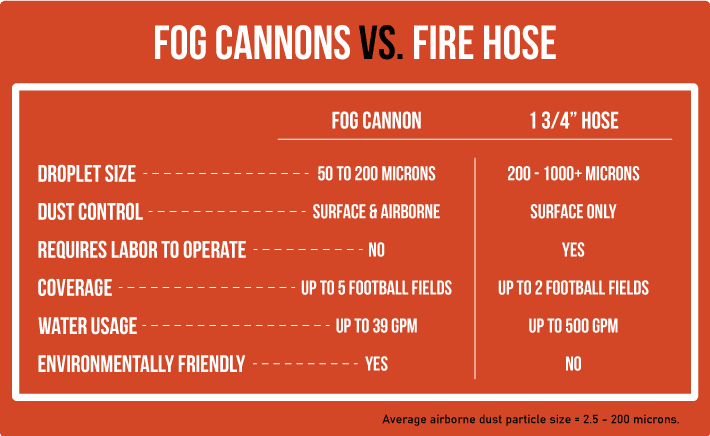

Demolition companies who engage in SMM have figured out that hoses don’t stop airborne dust. Most choose fog/mist cannons because they capture dust at the point of emission and pull it to the ground before it can travel across the site line.

HOW DOES A FOG CANNON WORK?

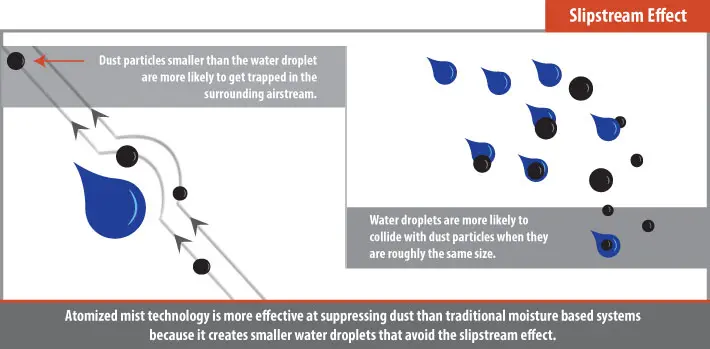

A “fog” or “mist” cannon uses a high-powered fan at the back of the machine to concentrate air through a cone-shaped barrel, raising its velocity as it exits the other side. Mounted on the front exit-side of the barrel is a ring manifold with multiple nozzles that fracture pressurized water into microdroplets roughly the same size as the airborne dust, which is the most effective approach for suppression.

The air forced through the cannon propels the mist, introducing a cone of millions of minuscule droplets into a defined area. Technically known as “atomized mist,” the fog is light enough to remain airborne and travel on air currents, colliding with dust particles and dragging them to the ground.

Droplets need to be roughly the same size as the particulates to capture them, otherwise, the droplet is propelled away. To extend the reach, some cannons use a booster pump which electronically increases the pressure instead of relying on innate water pressure, thus decreasing the amount of water needed. In contrast, hoses require labor and a massive volume of water, often resulting in excessive standing water & runoff. Due to the volume and pressure to propel the water long distances, hoses create large droplets that saturate the area. High water bills and increased man-hours raise the cost of operation and reduce safety in the work area.

CONSIDERATIONS WHEN CHOOSING A FOG CANNON

Here are some factors that help demolition contractors decide which fog cannon fits their needs:

Project Size & Scale - A fog cannon’s reach should match the relative size of the active area on the site. For example, some operators have a single excavator taking down a building with a front loader assisting in removal. This could require just a single mid-sized cannon, depending on how much dust is being generated at the sorting area.

Water Consumption & Availability – Access to hydrants can be limited or non-existent since, in some cases, hydrants need to be left unused in case of fire. Long stretches of hose makes the placement precarious with tires and tracks potentially rolling over them. The longer the hose, the lower the pressure at the nozzle, reducing reach. Regardless, hydrants release 75-100 GPM of water to hoses, which can lead to excessive pooling and runoff, in violation of some permits. Moreover, non-potable water can clog hoses and nozzles and require a separate pump.

Environment & Location – High-reach excavators with clamps or hydraulic hammers create dust high in the air that can travel long distances. Wind tunnels created by surrounding buildings can carry the dust farther. The wind is not just a factor in urban settings, but wide-open spaces with no barriers. Terrain is another consideration for the placement of equipment, making versatility and mobility a vital component

Power Source – Access to energy can be a challenge and having a designated power source for some equipment is important. Some cannons come with their own power sources on the same trailer.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

WHEN ARE FOG CANNONS NOT THE RIGHT TOOL?

Fog cannons are not the ideal solution for every project. High winds close to ground level can blow the fine atomized mist away from the target. Proper positioning upwind from the emission can remedy this, so as the particulates travel on air currents, the fine mist travels with them.

Cannons also require power to operate, which isn’t always available. There are designs to address these situations, such as the DB-60 Fusion, which is a self-contained unit featuring a cannon and a genset on a single trailer.

Water is required for the operation of every dust control technology that currently exists, and fog cannons are no exception. A fog cannon does not require a large amount of water, approximately 10 GPM of pressure, about the same as a garden hose. Using a built-in booster pump provides the pressure required. A built-in filtration unit allows the use of non-potable water from a local lake or river.

Ideal for sites lacking a viable power source, the DB-60 Fusion utilizes a trailer-mounted genset to provide mobile and versatile dust suppression.

WHAT ARE MY FOG CANNON OPTIONS?

The throw distance and coverage area of the units are determined by the power of the fan and the length/size of the barrel. If the cannon is mounted on a tower or high on a truck and the amount of power provided for optimum performance are additional considerations.

Indoor mist cannons – Performing indoor demolition on structures containing asbestos, drywall, and other materials that release potentially hazardous dust emissions can be done either by hand or using mini-excavators or both. Either way, it is dangerous for staff in the area, who will likely be required to wear personal protective equipment (PPE). Smaller industrial misters like the DustBoss® DB-10 or the DustBoss Atom® are compact and easy to maneuver by hand. Delivering a cone of mist 10 m (32 ft), the DB-10 provides excellent indoor dust suppression. For larger interior demolition projects, the DustBoss Atom is a fanless model that uses an engineered water stream delivered from a booster pump to offer precise indoor suppression.

Small outdoor mist cannons – Urban or suburban demolition projects can occupy a space as small as a single building or as large as a city block. This means that site lines are often tight and in close proximity to the public. To quickly capture airborne dust before it migrates beyond the site line, the plume of mist needs to reach precisely where the emissions are created. These projects often feature multilevel buildings, so the vertical reach of the unit should be considered. The DustBoss Atom is suitable for small outdoor sites due to its strong pressurized stream that reaches 30 meters (100 feet).

Mid-sized outdoor mist cannons – The demolition of a hospital or university property can involve several buildings over a large area. Generally conducted in phases corresponding with construction, demolition contractors should consider a mix of indoor, small, and mid-sized fog cannons for all aspects of the project. Many contractors choose the multi-purpose DustBoss® DB-30 for these types of projects. The DB-30 has a cone reach of 30 m (~100 ft) and a coverage area of up to 2,880 m2 (31,000 sq ft) when equipped with oscillation. It is also excellent for cooling outdoor worksites in high heat environments and is popular for hydration in the concrete curing process.

Large outdoor mist cannons – Major demolition projects like airports and supermalls can be measured in square kilometers of treeless area. This means site clearing of giant structures and large amounts of concrete with no wind barrier to stop hazardous dust from traveling well beyond the site line into local communities. Along with strategically placed small or mid-sized units for storage piles and active zones, demolition contractors working at this level often employ one or two large cannons to create a mist barrier against particulates. For greater coverage and reach, the most popular cannon is the DustBoss® DB-60. The DB-60 has a cone reach of 60 m (~200 ft) and a coverage area of up to 11,600 m2 (125,000 sq ft) when equipped with oscillation.

CHOOSING A DUST CONTROL CANNON

With profit margins as tight as they are, every equipment purchase needs to be strategic and necessary. With that in mind, our advice is:

- Buy versatility – Think about what you need now, then buy a machine that provides room for your operation to grow. Some machines allow a VFD to adjust the fan throw distance, offering increased adaptability. With different power options and either skid or wheeled carriage mounting, customisations are easy.

- Rentals are great for testing and supplementing – It’s hard to predict the needs of each project during certain seasons. Having a DustBoss on hand for each project and then supplementing them with rentals as needed is the economical option.

- Quality matters – For over 15 years, BossTek has delivered reliable dust suppression solutions. The first DustBoss machines sold are still going strong and require minimal maintenance. Many competitors can’t say the same.

- Consider the warranty – The standard DustBoss warranty for most models is 3 years or 3,000 hours, one of the longest in the industry.

NO MORE COMPLAINTS, NO MORE WASTE, NO MORE LABOR

Paying someone to stand with a hose in proximity to falling material and moving machinery is expensive, wasteful, and dangerous. The ROI for fog/mist cannons comes through lowering labor costs, reducing community complaints, and minimizing dust violations. Reputation goes a long way with both partners, regulators, and the community. Seeing a DustBoss in action often is enough to provide peace of mind to observers. Additionally, if it helps capture a project, then it pays for itself several times over.

STOP DEMOLITION DUST WITH DUST CONTROL TODAY!

Receive a quick quote and talk to a dust control specialist today to end fugitive dust!