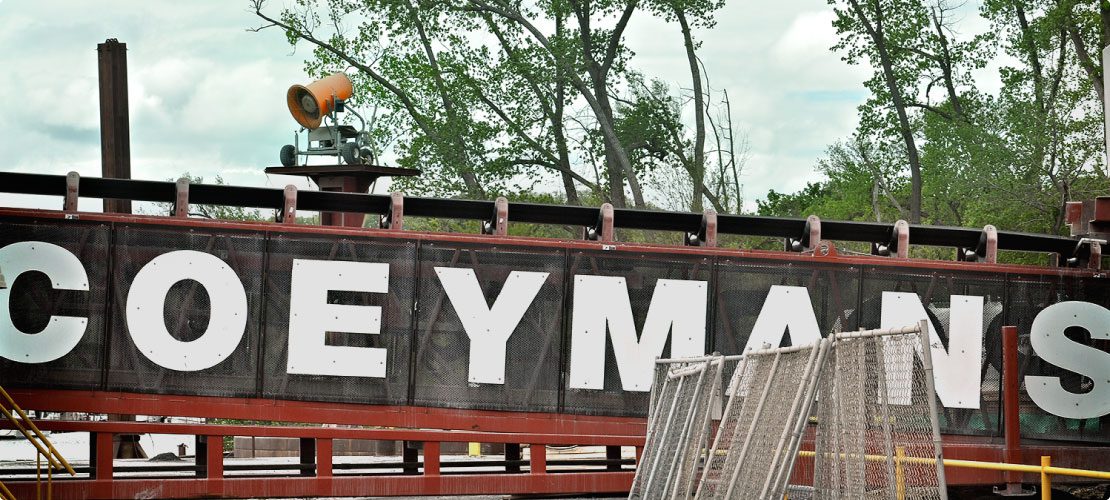

Mounted on a tower, the DB-60 suppresses dust over metal scrap recycling piles. The Port of Coeymans and Coeymans Industrial Park are located on the Hudson River in New York, 10 miles south of Albany and 110 miles north of Manhattan. Intended to relieve the burden on the congested New York City ports and offer the Northeast better access to waterways, the port loads and unloads many ships per day transporting bulk commodities such as clinker, fly ash, gypsum, bauxite, salt, grains and corn. It also acts as a major transfer point for bridge fabrication and building materials, including precast concrete and steel headed for large urban construction projects.

Operators started having concerns with air quality when the port began to regularly receive large vessels transporting clinker, a dry chalky substance used as a binder in cement products. Approximately 40-50 vessels per year arrive from Greece, Turkey, Egypt and Spain, delivering nearly 33,000 tons (30,000 metric tons) per week of the substance.

CAPACITY AND FACILITY

The 300-foot (91.4 m) wide dock receives vessels of up to 750 feet (228.6 m) LOA, with no beam restrictions, and a draft of 31 feet (9.4 m) or less. In addition, a 300-foot (91.4m) by 60-foot (18.3 m) inlet channel with a 15 foot (4.5 m) draft allows loading/unloading from both sides.

Dust suppression is directed to where it is needed most in the unloading process.

With easy access to the port, highway and rail transport, the Coeymans Industrial Park offers outdoor storage and transfer services. Once the materials are unloaded by either ship or ground transport, the raw cargo is moved and organized by front loaders into separate storage piles, ready for the next step on its journey. In addition, the surrounding urban areas use the park for scrap metal storage intended for a nearby recycling facility.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

DUST GENERATION

When the ships arrive, large clamshell shovels controlled by tower cranes unload the material from the cargo hold, over the deck -- from 25 (7.5 meters) to as high as 120 feet (to 36.5 meters) in the air -- to a 20 foot tall (6 meter) hopper, which discharges into a 40-ton (36 metric ton) haul truck. The truck drives the material the short distance to the adjacent industrial park, where it is stored for further transport.

Operators observed that dust emissions were generated particularly when the substance was dropped into the hopper. Although a baghouse was attached, a percentage of the dust emissions would still escape. In addition, the facility needed dust suppression for scrap metal storage and other operations in the industrial park. According to port managers, production growth has been followed by an increase in dust-causing activity, necessitating improved air quality.

With dust a potential issue throughout the port and storage area, operators realized that they needed a versatile and mobile solution which could deliver dependable suppression at a variety of locations. The goal was to improve air quality for the safety of personnel and inhabitants of the surrounding community.

CAPACITY AND FACILITY DUST MANAGEMENT FOR PORTS

Whether disrupted by wind or machinery, substances such as clinker and fly ash release small, lightweight dust particles. Like many other facilities handling bulk materials, the Port of Coeymans limits fugitive dust emissions by employing some simple methods.

- Crane operators limit the distance the dust-emitting cargo travels from the ship’s hold to the dock. This is done by using a clamshell shovel suspended from a crane to slowly unload the material into a tall portable hopper with a baghouse dust collection system.

DustBoss systems operate in harmony with crane operations.

Crane operators further mitigate dust by reducing the amount of material collected by the shovel in each pass. Although this extends the unloading time, it curbs the amount of material escaping from the top or sides of the shovel and thus further limits dust emissions.

DUST MANAGEMENT FOR INDUSTRIAL PARKS

Another area that needed dust suppression was the industrial park. Located about 700 feet (213 m) inland from the Hudson River with no natural wind barrier, the surface is a combination of concrete, packed earth and gravel. Scrap metal from various sources (demolition projects, old cars, dismantled ships, etc.) is transferred from barges and deposited into storage piles. During windy conditions, the unprocessed metal can emit dust both during offloading from vessels and loading onto ground transport.

The industrial park also stores mounds of various raw commodities. These well-organized piles, stretching as high as 20 feet (6 meters), are exposed to outdoor conditions and can emit dust in moderate winds, during offloading by haulers, disruption by front loaders and loading into trains or trucks. Additionally, the heavy ground equipment can kick up its own dust during normal operations.

Managers explored the option of assigning several workers to use hoses in different locations to wet down cargo, storage piles and driving surfaces. However, hoses have been found to offer inadequate suppression of airborne particles, covering a limited area and requiring a hydrant using as much as 75 GPM (284 lpm) of water. The approach creates standing water and runoff, and can raise the cost of labor, since hoses need to be manually operated.

MOBILE DUST CONTROL

Port managers decided to rent two of the mid-sized DustBoss® DB-60 cannons from BossTek® to test them out, eventually deciding to purchase both units. The cannons are mounted on heavy-duty wheeled carriages with a pintle hitch towing attachment.

The compact size of the DustBoss allows easy positioning in addition to automatic operation.

A 25 HP fan producing 30,000 CFM (849.50 CMM) of air flow propels the engineered mist in a 200-foot (60 meter) long cone that reaches high over the deck of ships. This type of coverage delivers simultaneous surface suppression to material in the cargo hold and airborne suppression through the shovel’s path from the hold to the hopper.

Approximately the height and length of a standard golf cart and weighing around 1800 lbs (816 k), the cannon is easily moved by pickup truck from the port to the industrial park. There, operators can cover more than 125,000 square feet (11,613 square meters) of the storage and traffic area by using full oscillation. Port of Coeymans uses municipal water supplied through a hose with a cam-and-groove quick disconnect coupling. The booster pump raises the pressure to approximately 160 PSI (11.03 BAR).

The unit features a 200-foot reach, 359° oscillation and 50° vertical adjustment angle.

Powered with a 100 foot (30.48 meter) 6/4 electrical cord, the machine is controlled by a touch screen panel encased in a NEMA 3R cabinet, which allows operators to adjust oscillation, booster pump, fan and water flow. The cabinet is constructed for outdoor use, designed to provide protection against dust, water and incidental damage. An on/off switch is placed on the outside of the cabinet for easy setup and control.

There are some clear benefits over the use of hoses. The DB-60 uses only 26.7 GPM (101.1 lpm) of water, delivering a much larger coverage area and requiring no labor for ongoing operation. Workers at the Port of Coeymans simply place it in the desired location, point it in the right direction, hook up the hose and power, turn it on and walk away.

ATOMIZED MIST CANNON POSITIONING

When raw commodities are being unloaded, one DustBoss is positioned to cover the long path of the crane shovel from the hold to the hopper. Located upwind and shooting atomized mist over the ship, the wind current is used to direct larger droplets to settle gently on cargo in the hold, offering surface suppression to mitigate dust production caused by the disruption of the shovel. The wind also carries smaller droplets in the path of the dust where particles are most prone to become airborne, providing effective suppression virtually at the point of emission.

The mist can be seen stretching across the deck to deliver efficient dust suppression.

Also, mounted on its wheeled carriage, the other DustBoss is secured on a 12-foot tall (3.6 m) platform overlooking the dock. Along with the tower’s ability to rotate, the cannon uses 180º of oscillation to suppress airborne particles. Fugitive dust emissions are immediately met with atomized mist droplets that prevent the particles from traveling long distances. Like the unloading scenario above, the heavier droplets settle quickly, offering surface suppression without saturation, standing water or excessive creation of mud as workers, machinery and vehicles move through the area.

RESULTS

Operators report that air quality at the port has significantly improved during the unloading of clinker and other dusty materials, and that fugitive emissions have not been seen leaving the site since adding the units to the facility’s dust management plan. The cannons are easily positioned on the dock, taking up little room and covering a large area, allowing crane operators to transfer material from hold to hopper more efficiently.

The industrial park has experienced a noticeable improvement in air quality, especially when a DB-60 is in operation during dry and windy periods. Surface suppression allows trucks, front loaders and haulers to move more freely with less concern for dust creation. Overall, dust caused by disruption of material being loaded or unloaded has been drastically decreased, while no extra labor is needed to handle hoses.

For most port operations, water (plain or chemically treated) is currently the only practical method of suppressing airborne dust in outdoor operations. When handling bulk cargo in a port and industrial storage setting, mobile atomized mist technology propelled by powerful fans has displayed the ability to suppress fugitive emissions for nearly all bulk materials in normal weather conditions, both at the terminal and in the storage yard. Consuming considerably less water and producing smaller droplet sizes than competing sprinklers and hoses, industrial atomized mist helps operators stay compliant with both air quality and wastewater runoff regulations.

IMPLEMENT DUST CONTROL TODAY!

Receive a FREE quote and talk to a dust control specialist today to end fugitive dust!