The evidence regarding the impact of dust particles on the environment and human health is pretty damning. Humans have known dust will kill us since we started covering our mouths with cloth on windy days about 150,000 years ago -- give or take a millennium or two. However, the scientific evidence around the effects of dust emissions on the environment and human health is far more recent, only around 100 years. This article dives into the most recent scientific findings around dust emissions and why it is so critical that we understand the hazard and use the latest technology to control it.

In the not-so-recent past, when chronic breathing issues were linked to early death for workers across several industries, lawmakers were pressured to act. It was only in the ‘90s that the US Congress and agencies like the Occupational Safety and Health Administration (OSHA) took decisive action against industrial dust emissions with stiffer regulations. Companies that potentially emit dust experience higher health insurance premiums due to an increase in worker claims. Sites with violations may see higher premiums than standard, dramatically increasing the cost of operation and making them less competitive.

Although community attitudes are shifting to the side of better air quality, the environmental policies of many states and counties in North America still lean on the side of industry with limited regulatory standards and minimum budgets for local environmental regulators. Despite evidence to the contrary, there has been some dispute from industry advocates over the environmental impacts of fugitive dust. Some might argue less regulation is “business-friendly,” but in reality, it is doing operators no favors. Rather than regular visits by Environmental Protection Agency (EPA) investigators who test air quality and discreetly hand out fines, the only recourse for workers and surrounding communities affected by dust is to engage in highly publicized civil lawsuits seeking million-dollar settlements.

The challenge is suppressing dust and controlling airborne emissions. With new regulatory testing standards of smaller – nearly invisible -- particles, operators are finding that older dust control methods (hoses, sprinklers, tanker trucks, etc.) are expensive, use excessive water, and don’t control regulated dust once it is airborne. The latest misting cannon technology controls dust at the point of emission, improves workplace air quality, and prevents emissions from leaving the site line for a lower impact on the health of the community and the surrounding environment.

ENVIRONMENTAL RISK OF DUST EMISSIONS

As dust from industrial activities travels on air currents, before it reaches humans, it distresses the flora (plants) and fauna (animals, insects, fish, birds, etc.) surrounding the site. According to the study, The effects of dust on vegetation—a review, which studied dust emissions from a quarry on the local vegetation, “The effects of dust on crops, grasslands, heathlands, trees and woodlands, arctic bryophyte and lichen communities are identified. Dust may affect photosynthesis, respiration, transpiration and allow the penetration of phytotoxic gaseous pollutants. Visible injury symptoms may occur, and generally there is decreased productivity.”[1]

The impact on the local environment cited by the research is a reduction in the ability of local vegetation to clean the air from naturally occurring atmospheric particulates (dust from erosion, changing wind patterns, forest fires, etc.). Moreover, a degradation in nearby crop yield and crop quality can diminish the productivity of the local economy.

The effect on proximate domesticated farm animals and wildlife is profound. Conclusions from environmental studies by the Canadian government concluded, “Air pollutants can poison wildlife through the disruption of endocrine function, organ injury, increased vulnerability to stresses and diseases, lower reproductive success, and possible death.”[2] This research is still early in its development, but as it becomes clearer, local ranchers and livestock industries (beef, pork, poultry, milk producers, etc.) could point to dust emitters for any loss of production and profit tied to reduced air quality.

This is not to say that the agriculture and ranching industries don’t contribute to the problem of air quality. Although it happens only two or three times per year, dust emissions from agricultural harvesting and sowing can lower air quality tremendously across an entire region. This is also true from livestock movement and wind erosion due to over-grazing.

The research from Canada further points out that -- along with birds and mammals -- insects, worms, shellfish, and fish all interact with their environment in different ways. Wastewater runoff control from industrial activity is a major part of keeping waterways clean. Sprinkler and tanker truck systems average between 100-500 gallons per minute (GPM). Any DustBoss mist cannon can significantly reduce the volume of water used for dust control and be a sustainable solution for waterways affected by runoff. Even the largest mist cannon model BossTek offers, the DustBoss DB-100, uses a maximum of 39 gpm for a coverage area of up to 5 American football fields.

As for airborne dust, each animal's exposure and susceptibility to the impacts of particulates can be distinctive. When operators resist addressing their emissions, the long-term effect on the airshed can distress environments miles away. “An airshed is the volume over an area of land in which airborne [substances] travel to reach a particular river, lake, bay, or other body of water given the area of the land surface.”[3] This further proves the need for airborne dust control, which is largely achieved only with atomized mist. This is especially true of the smallest and most harmful particulates such as heavy metals and respirable crystalline silica, which top the list of the most harmful emissions for the health of humans, flora, and fauna.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

CONTROLLING RESPIRABLE CRYSTALLINE SILICA (RCS) EMISSIONS

RCS is a highly regulated substance by the Mining Safety & Health Administration (MSHA), EPA, and OSHA for its connection to the lung diseases silicosis, pneumoconiosis (black lung), and chronic obstructive pulmonary disease (COPD), as well as lung cancer and kidney disease. Developed into a crystalline structure over millions of years, geologists estimate thirty percent of all minerals are silicates (minerals containing silica), and that up to 90 percent of the earth's crust could be comprised of silicates.[4]

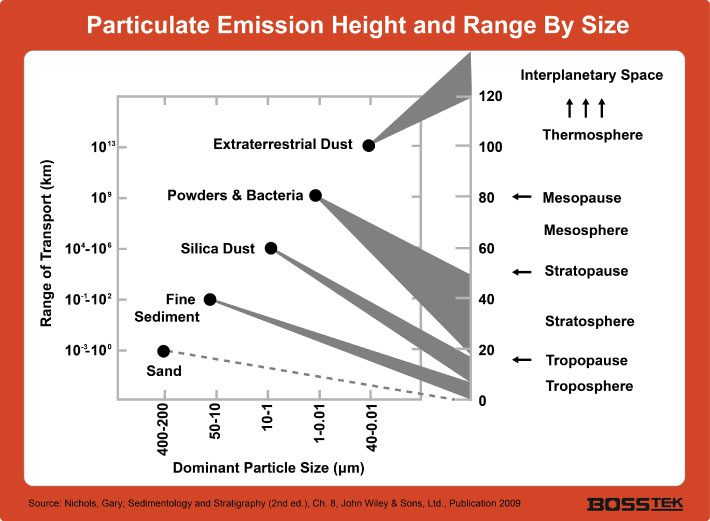

The size of RCS generally makes it small enough to be invisible to the naked eye and bypass the body’s natural defenses. The crystalline structure allows it to attach to soft tissue, making it chronic and deadly over long periods of exposure. According to the National Institute of Environmental Health Services, the size of dust emissions from substances containing silica varies from .01 microns (μm) to 100 μm in diameter.[5] For perspective, the diameter of the average human hair is about 100 μm. Depending on their weight, dust particles must typically be 200 μm or smaller to become airborne and linger, while 50 μm and smaller particles are nonvisible to the naked eye.

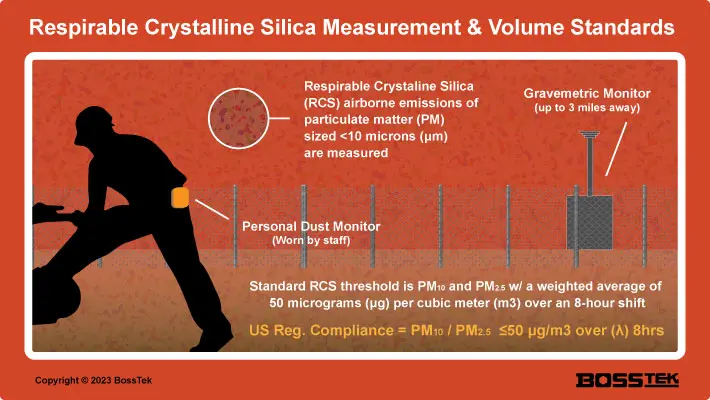

Figure 1: Respirable crystalline silica measurement and volume standards.

That’s why regulators test for RCS and other small dust particles in the air for levels of Particulate Matter (PM) of 10μm (PM10) and 2.5μm (PM2.5) of a weighted average of 50 micrograms (μg) per cubic meter (m3) over an 8-hour shift.

US Reg. Compliance = PM10 / PM2.5 ≤50 μg/m3 over (λ) 8hrs

Personal dust monitors (PDMs) and gravimetric monitors are used to measure the approximate size and volume. Since RCS is so prevalent, nearly every bulk handling activity is monitored:

RCS in Mining & Tunneling – MSHA monitors underground operations from coal to transit construction. Rules are especially tight around operations that involve quartz.[6] Operators with underground power restrictions choose non-electrical misting systems.

RCS in Construction & Demolition - Storage and cutting of concrete is a major source of RCS. Both indoor and outdoor demolition dust emissions are particularly monitored and should be controlled by a misting cannon. OSHA has a special section covering construction dust.[7] Toxic dust from procedures like asbestos abatement also can require specialized indoor misting systems.

RCS in Cement Production – Many constituents of cement, from limestone to sand, shed RCS through conveyor transport and transfer. The calcining process dries and reduces the mass of the meal, increasing emissions, so calcined material should be closely monitored and dust emissions addressed at all stages of production.[8]

RCS in Bulk Handling and Ports – The storage and movement of raw bulk materials by equipment and conveyors can have a significant impact on the surrounding environment, particularly in ports with direct proximity to waterways with increased wind conditions.

LANDFILL DUST AND BACTERIA

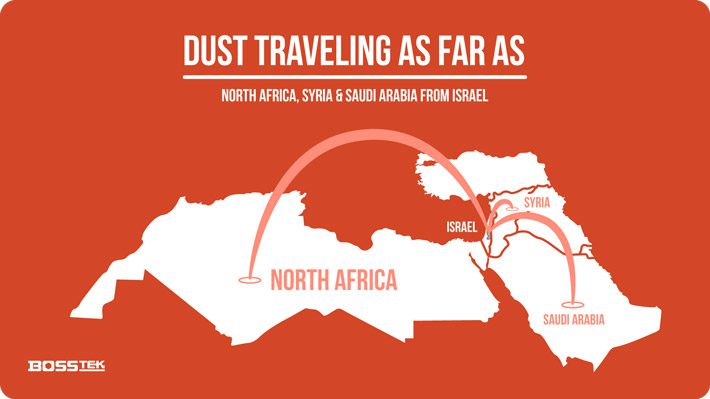

A 2022 study was published in the Journal of Geophysical Research: Biogeosciences that analyzed airborne dust collected in Rehovot, in North Central Israel, revealing some never-before-known insight into dust from landfills. Using DNA sequencing, researchers tested bacteria and found that bacteria can attach to particulates and become airborne, travelling with it. The dust carries diverse bacterial "communities" to locations hundreds, or even thousands, of miles away. Using trajectory modeling, they found some of the dust they studied came from places as far as North Africa, Saudi Arabia, and Syria. The settling dust and attached bacteria can alter environmental chemistry and affect human and animal health.[9]

The conclusions from this study back up some of the assertions found in a 2019 survey analysis of 100 households within 100 – 2000 meters (.06 – 1.2 miles) of the Thohoyandou Landfill in Northeastern South Africa. Those researchers found that 78% of participants living near the landfill site indicated a serious issue with air quality, leading to illnesses such as flu, eye irritation, and weakness. More than half of the participants (56%) living closer to the landfill indicated fear for their long-term health.[10]

These studies reveal the new developments in our understanding of landfill and recycling dust emissions. Emissions from waste and recycling operations were considered similar to any other dust from any other industry. In some cases, particulates from C&D can contain RCS or heavy metals, while MSW, as the research shows, can carry potentially harmful bacteria. These MSW emissions are regulated as air pollution and have not yet been recategorized or tested according to the new findings. However, this may change in the future, and these types of studies can potentially be used to inform future regulation.

Figure 2: When atomized spray control systems produce droplets approximately the same size as airborne particles, they deliver a greater attraction between droplets and dust.

HOW MIST CANNONS HELP THE ENVIRONMENT

When operators see environmental regulations, they naturally see dollar signs flying out the window. However, those dollar signs might as well be stamped on every fugitive dust particle, because having inadequate dust control will cost far more in violations and potential lawsuits. Field tests have shown that operators can reduce their environmental impact, improve compliance, and lower operating costs using atomized misting technology.

Why are misting cannons better than hoses, tanker trucks, and sprinklers? It comes down to the slipstream effect.

Using pressure to propel the water makes hoses, tanker trucks, and sprinklers produce droplets that average 200-1000 μm in size. Droplets above the size of 200 μm are too heavy to be suspended for more than a few yards by normal outdoor ambient air currents before they fall toward the ground, causing the air to rapidly flow around it, creating a “slipstream.” Imagine a car driving rapidly through the snow with only a few flakes touching the windshield. Like the car, but on a microscopic scale, the airflow around a falling droplet is strong enough to deflect smaller airborne particulates, in some instances providing lift. In contrast, atomized mist droplets -- ranging between 15 to 200 μm -- linger in the air with virtually no slipstream, travel with airborne dust, collide with particles, and drive them to the ground.

The impact of large heavy droplets can kick up dust when sprayed onto storage piles. Atomized mist settles lightly on material surfaces, offering ground-level suppression as well. When used in tandem with a surfactant and dosing pump, the technology is effective on an extremely wide range of hydrophobic applications and materials.

Dust cannons have a powerful fan in the back and a misting ring in front where pressurized water is fractured into tiny droplets propelled by the air current created by the fan. The mist is released in a cone that can be directed at a specific work area or oscillate to cover a wide area. Once the hoses and power are attached, automated operation reduces labor costs considerably. Programmable controls and remote operation can improve suppression efficiency even further, particularly in high-volume production operations. The Fusion Misting Cannons are roadworthy trailer-mounted designs equipped with their own generator sets, and other options for remote locations without an electrical source.

REDUCE ENVIRONMENTAL IMPACT WITH MIST CANNONS

Environmental sustainability, improved air quality, and workplace safety are key components behind BossTek’s development of its industrial dust control products. The goal is to design and produce field tested systems that are long lasting with a low cost of operation and greater compliance.

By integrating mist cannon technology into an environmental management air quality plan, a company shows that it cares about the health of employees, the community, and the environment. BossTek experts consult with operators on how to best utilize DustBoss technology in their operations to control airborne fugitive emissions and improve suppression. Contact us today to discover a cost-effective path to better environmental stewardship.

MITIGATE RISKS FROM HAZARDOUS DUST PARTICLES TODAY!

Receive a FREE quote and talk to a dust control specialist today to protect against fugitive dust!