A pioneer in dust and odor control equipment has helped an aluminum die casting company cool its operations and create a more pleasant working environment by employing powerful air cannon technology. LeClaire Manufacturing is using two DustBoss® DB-30™ dust cannons from BossTek® to improve airflow, reduce indoor temperatures and direct air toward internal ventilation systems. The result is a cooler workplace and improved worker morale.

The DustBoss® can be specified with a 359° oscillation for on-site operations.

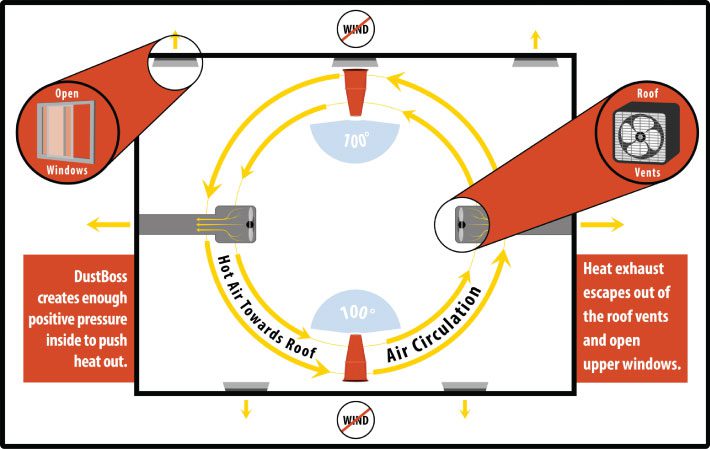

Open windows, wall fans and large ceiling-mounted fans do little good without enough positive pressure inside to push a significant amount of warm air out. “The building was adequately designed for airflow, and we have several fans in place, but if the air outside is stagnant, the heat just hangs in the building and becomes very uncomfortable,” said Rob Zimmerman, Co-President and Owner of LeClaire. “We definitely needed a solution.”

The shop housing several furnaces has ten large windows, five approximately 8 feet (2.4 m) from the ground and five approximately 20 feet (6 m) from the ground. Heat generated from the production process rises toward a 38-foot (11.5 m) pitched ceiling with two high-velocity exhaust fans connected to vents.

Radiating heat spreads from each furnace and stretches throughout the shop. The lack of adequate circulation can cause the heat to stagnate, and the summer humidity can weigh down the hot air, slowing its ascent or causing it to remain idle. As hot air rises and collects in the pitched roof, the two high-velocity exhaust fans struggle to keep up, particularly with the addition of summer heat outdoors.

For hot air to more efficiently exit open windows and roof-mounted exhaust vents, wind is an essential ingredient. As wind passes the windows and vents, the low pressure outside pulls the heat out. Without the higher pressure indoors, only the heat in direct proximity exits the windows, and exhaust fans need to work harder to pull heat out of the vents. Direct wind or high wind velocities can blow into open windows, creating circulation and cooling the air, but it’s rare for the area in the summer.

Along with exhaust fans, other methods have been used at ground level to help promote air movement and offer relief. Fans were placed periodically along the shop floor to aid in air circulation. At each of the seven workstations, portable air conditioners were also placed to keep the immediate area cool for each worker. In a large area like the molding department, none of these methods adequately achieved its goal.

“We read an article about how a DustBoss® had helped another die cast operation with air circulation, so we decided to rent two DB-30 units for a summer,” Zimmerman said. “When they arrived, we were immediately impressed."

DustBoss machines create circulation throughout facility.

Originally designed for dust suppression in large outdoor industrial settings using atomized mist nozzles, operations with high heat indoor environments such as die casting, smelting and glass production have adopted the technology for effective air circulation.

The DB-30 has a standard 480V / 3-phase motor running an industrial 7.5 horsepower fan generating 9,200 CFM (260.50 CMM), located in the rear of a specially engineered cone-shaped steel barrel. With the fan blades shielded by a heavy mesh guard, the unit draws air from the wide opening in the tail and forces it down the cone toward the narrower mouth in front. Compressing the air down the barrel increases velocity and directs the discharge.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

Since the DustBoss is engineered to operate outside, large area coverage and mobility are key elements to its effective, compact design. Mounted on a mobile carriage, the golf-cart sized unit weighs approximately 800 lbs (363 kilograms) and can be easily maneuvered with a fork lift wherever it is needed.

The DustBoss DB-30 is small enough to easily operate and relocate as needed.

At LeClaire, the units were positioned at an opposing wall, near the lower windows and pointing toward each other. Able to oscillate 359º and adjust vertically 0-50º, operators programmed the units to cover an arc of about 100º, drawing air inside from the low windows.

RESULTS

After experiencing a warmer than average summer, the LeClaire staff reports that the units definitely achieved their goal of cooling the area and promoting air circulation. Operators commented on the rugged construction and ease of use, being able to input the machine’s settings on the touch pad and walk away.

"We could tell these machines were built to last and would require very little maintenance."

Rob Zimmerman - Co-President and LeClaire Owner

“We could tell these machines were built to last and would require very little maintenance,” Zimmerman said.

Upon learning that a used DB-30 and the more powerful DB-60™ generating 30,000 CFM (849.50 CMM) had become available for purchase, managers jumped on the opportunity.

“After using our rental DB-30s all summer, we realized there’s about an 8-month window out of the year that we would need these machines, so we just bought a couple,” Zimmerman concluded. “The increased power of the DB-60 is going to go a long way to further improving circulation. In fact, we’re going to see if the setup we have now will work through the next summer, and then consider adding another DB-60 later."

STOP DEMOLITION DUST WITH DUST CONTROL TODAY!

Receive a FREE quote and talk to a dust control specialist today to end fugitive dust!