The need for soil remediation is generally specified in environmental assessments prior to any earthmoving project. The soil samples taken by the environmental professional can be deep enough to detect odors because, in many cases, odors don’t need much ground cover to remain hidden. However, what the environmental assessment may not be able to definitively report is the intensity or volume of the odor emission. Whether the soil is being sequestered into settling ponds, moved into enclosed/covered storage areas, or loaded for transport, Environmental Managers mitigate odors at the point of emission on the molecular level by using odor control misting systems. Many have found this method reduces or eliminates complaints that trigger agency interventions.

Depending on the emission intensity and type of the “nuisance odor,” as defined by the U.S. Environmental Protection Agency (EPA), odors can be considered a health hazard. The attention of inspectors is heavily influenced by responses from the community. Even short-term exposure can garner a swift and decisive reaction prompting inspections from local agencies and potential lawsuits.

The OdorBoss® creates a fog with droplets small enough to treat odor on the molecular level.

SOIL REMEDIATION ODOR REGULATIONS

The management objectives of the EPA concerning odor emissions from soil remediation are broad.[1] Regulators are tasked with working with operators to minimize odor emissions and their impacts. They make sure EPA-licensed sites do not expose communities to unacceptable levels of odorous emission. Inspectors ensure that industries manage odor emissions within the accepted criteria by applying ongoing risk evaluation and management principles that evolve as scientific understanding of odors and their potential health effects increase over time.

The Centers for Disease Control’s (CDC) Agency for Toxic Substances and Disease Registry (ATSDR) include industrial odor emissions as part of its scope of work. Tasked with investigating odor complaints, the agency recommends that emitters or potential emitters keep an Odor Diary as part of odor-producing operations.

However, unless the site is a federal project or EPA regulated, enforcement and additional rules fall to local governments. An example of the high cost of local regulation can be found in states like New Jersey,[2] which have strict guidelines around odor. First offense odor violations range from $150 up to $1,400 but get subsequently more expensive. Continuing violations may be subject to penalties of up to $15,000 per violation. These can be assessed daily.

All of the violations and fines depend on how inspectors measure and describe (rate the intensity of) the odor. Although some local governments have different measurement guidelines, many inspectors (including the EPA and CDC) use these general description guidelines for odor based on detectability, nuisance, and effects on local communities:

Low – Not intense or frequent enough to create a nuisance, affect health, or change the routines of the local community.

Medium – Intense at times, may cause some physical reaction (nausea, headaches, etc.) and could cause the local community to stay indoors or change plans when the odor is unpleasant. This could lead to government inspections and regulatory intervention.

High – Persistent and intense odor that may cause an immediate physical reaction such as coughing, nausea, or vomiting. Likely will be followed by swift regulatory action, including possible shutdown until corrective measures can be implemented.

IS ODOR CONSIDERED A POLLUTANT?

According to ATSDR, the answer would be “yes.” A pollutant is defined as an emission that adversely interferes with health, comfort, property, or the environment of the people exposed to it. Most pollutants are introduced in the environment by sewage, waste, accidental discharge of by-products, or residues from the production of something useful.

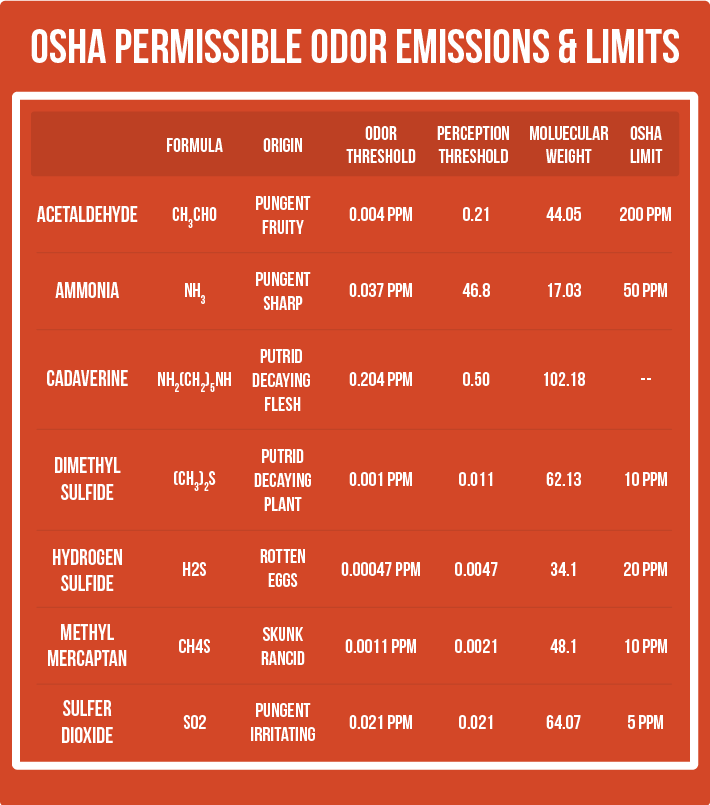

The Occupational Safety and Health Administration (OSHA) has posted guidelines around permissible gas emissions and limits.[3] Many gasses are odorless, so in the chart below we pulled some of the potential main causes of odors from soil remediation. These are tested by inspectors through an “olfactometer,” either in the field or in the lab from air samples.

SOURCES OF SOIL REMEDIATION ODORS

Removing the top layer of soil can reveal years of odorous buildup. There are three main sources of soil odors:[4]

Spilled chemical contaminants – There are dozens of industries where processes dating as far back as the 19th century left hazardous chemicals hidden under the soil, requiring remediation. Sites of abandoned oil refineries, chemical production plants, industrial animal processing, mining material processing plants, etc. can leave odorous deposits. Airborne odor control may be compulsory, as some of these emissions may be considered toxic.

Exposure of decomposing biosolids or contaminated groundwater – In some cases, impounds of animal waste, mining tailings, unlicensed landfills, chemical seepage into the water table, and contaminated soil left over from previous flooding can require soil remediation. The odor emissions released from these sites likely require an airborne control.

Gaseous deposits – Aside from methane, which is explosive, large odorous gaseous deposits that are naturally occurring or remain from previous industrial activity can pose a nuisance and potential hazard to both the workplace and surrounding communities. Soil remediation may involve pockets of gas that allow controlled release (or capture), but for the most part, airborne deodorization will likely be required.

READY FOR A QUOTE?

Talk to a dust control specialist and get a quick quote for your project.

HOW DOES INDUSTRIAL ODOR TRAVEL?

The reason why soil remediation odor control is so difficult is that the odor-causing substance is generally spread over a wide area. Controlled or minimized exposure by slowing the removal of tainted soil extends timelines and budgets. Moreover, there may be undetected pockets of highly concentrated odorous material, the release of which may require immediate and direct airborne treatment beyond the already established controls.

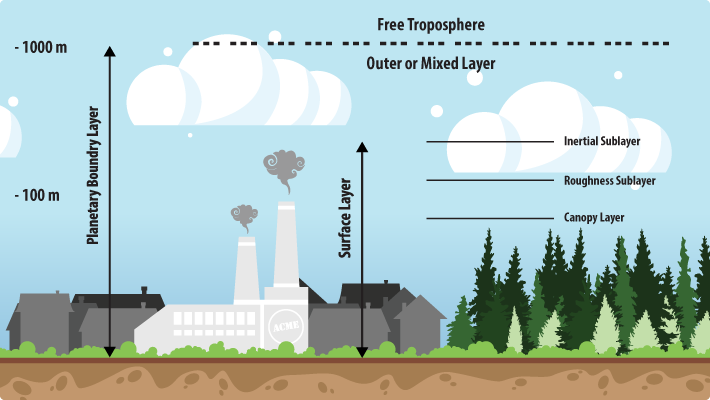

Odor travels quickly on wind currents and can easily be spread over a wide area. Gaseous airborne odor molecules can move rapidly in all directions, frequently colliding with each other. The average speed of a molecule depends on its mass, as well as the temperature and wind speed. Heavier particles move slower than lighter particles. In higher temperatures, all particles gain kinetic energy and move faster. Lighter molecules like oxygen and nitrogen in the air at normal temperatures -- 65º-75º F (18º-23º C) -- drift between 1000-1300 feet per second (300 to 400 mps).[5]

When odor emissions from soil remediation reach upper atmospheric layers, complaints can come from miles away.

Dispersion can certainly dilute the smell, but over time, the foliage, soil, and other materials absorb the odor, causing a lingering and underlying scent that permeates the surrounding area. This can deter new visitors to the area, lower property values, and sour the reputation of the contractor tasked with remediation, making it hard to obtain new permits and operate in other areas for the same type of project.

METHODS OF ODOR CONTROL FOR SOIL REMEDIATION

Too many contractors make the simple mistake of choosing the cheapest possible odor control method and adjusting the methodology as complaints mount. Violations, forced downtime, and investing in new ineffective methods degrade profit margins until the contractor may have paid three to four times the cost of a field tested and effective method.

Three factors in effectively controlling odor:

- Address it quickly at the point of emission.

- Use the correct chemical to suppress the odor.

- Active methods work better than passive methods.

Passive methods don’t move or react to changing conditions. Active methods, though requiring more labor and investment, are generally mobile, reactive, and more effective against changes in conditions such as wind, hot days, or increases in emission intensity.

Perhaps the most affordable method is a natural barrier of tall dense trees around the site line that can reduce the amount of wind and absorb some of the odorous molecules. Unfortunately, soil remediation is often done in open areas and natural barriers take decades to create. This is a passive method.

A misting barrier of fencing or poles with hoses attached is an option, but generally does not offer the reach required to be entirely effective. For example, if the source of the odor is in an open field surrounded by a 6-foot-tall odor mist barrier and the odor is released 100 feet away, it will likely rise far above and avoid the odor mist barrier. This is a passive method.

Topical sprays can provide surface suppression for areas not being disrupted.

Sprayed topical foam requires a worker(s) actively spraying exposed soil with a treated biodegradable chemical that seals in the odor. This active method of surface suppression is effective but can be expensive from a labor standpoint. It can also directly expose staff to emissions and put them close to active machinery.

An odor control fog cannon like the OdorBoss® (OB-60G) uses an engineered misting head with a high-powered fan pushing millions of tiny droplets with the proprietary chemical additive OdorVore® into the air at the point of emission. The fog is light enough to travel with the odor molecules and collide with them, triggering the chemical reaction that removes the odor. The cannon is mounted on a mobile carriage that is easily moved by a pickup truck and is automated, running without active labor.

Odor control systems, like the OdorBoss, provide airborne suppression by targeting odorous molecule at the point of emission.

TYPES OF ODOR CONTROL CHEMICALS FOR SOIL REMEDIATION

Masking agents introduce another smell intended to overpower, improve, or dilute foul odor emissions. Chemical masking agents are formulated to be delivered as a fine spray or as a concentrated additive but are largely considered to be inadequate on an industrial scale.

Topical Foam is a biodegradable chemical treatment for organic compounds that is distributed from a chemical tank by hose with a foam-aerating nozzle. It traps gas emissions by forming a protective coating over the soil. The benefit of foam is that the operator can visually confirm full coverage.

Deodorizers (like OdorVore) are considered highly effective control for most industrial odor emissions, since they treat odors on a molecular level by removing the odor-causing element. OdorVore is a biodegradable formulation that is completely safe to plants, animals and humans. It is dispensed at a ~500:1 water-to-chemical ratio using the OB-60G cannon. The airborne delivery system relies on engineered droplets small enough to travel long distances on ambient air currents with odor molecules and interact with them.

ODOR CONTROL MIST CANNON

An industrial mist cannon distributes an engineered fog with millions of tiny chemically enhanced droplets into the air. It has a special open-ended barrel design containing a powerful fan on one end and an atomizer nozzle on the other. The fog is propelled by a 25-horsepower fan generating 30,000 cubic feet per minute (152.4 CMS) of air flow. Using the standard 180° built-in electric oscillator, as well as a vertical adjustment between 0-50º, it has an extremely wide dispersal with expanded reach and precision aiming.

The device is mounted on a towable roadworthy trailer that is also fitted with a 500-gallon (1893 L) water tank, designed to be moved and adjusted with changing conditions. The low-maintenance unit runs for 16 hours on a single tank under normal operating conditions.

CHECK OUT THIS SOIL REMEDIATION CASE STUDY

OdorBoss is the most effective technology on the market for controlling odors from soil remediation. Meticulously engineered technology and proprietary environmentally friendly deodorizers combine to create a lasting solution from one project to the next. They are also available for rent, so inquire about a dealer and availability in your area.

STOP ODOR EMISSIONS AT THE SOURCE

Receive a FREE quote and talk to an odor control specialist today!