Past large misting cannons and nozzle-based fogging systems, industrial dust collectors are a large source for dust control. Their applications vary from the two water-based systems and provide optimal dust suppression in operations where water is not wanted. Learn more about how all three of the systems are effective solutions to remove dust from the air.

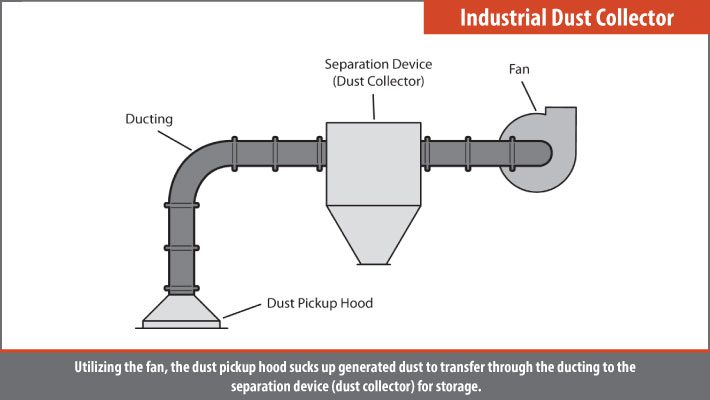

Industrial dust collectors are born and bred for the indoor application of dust control at industrial & construction sites, and their design matches that application. These systems suck up the generated dust using a high powered fan, ducting and a dust pickup hood to collect the unwanted particles in a separation device. The more the system is used, the more the particles it collects. Eventually, the device will need to be emptied, dumping the dust in another location.

While misting cannons do drop dust, the use of water can be undesirable in certain buildings or general facilities. Industrial dust collectors don't rely on water for dust suppression, so they can provide excellent indoor dust suppression if cost is not an issue.

This design is the foundation of dust collectors that is expanded upon in different variations of the system. Each job site is unique and the industrial dust collector offers in-depth customization with each of its parts to create a potent dust control system.

INDUSTRIAL DUST COLLECTOR ADJUSTMENTS

Since dust collection systems don't act as a prevention method to dust, one of the biggest factors that determines the build of the dust collection system is the actual material that is going to be collected.

Not all material is going to act the same. Some materials are going to be heavier than others, and the heavier it is, the more air and velocity is needed to effectively suck up the dust particles.

If a facility wanted to use a dust collection system to collect silica dust from indoor concrete cutting and used the exact same system to collect wood chips in another area, the system would either be too strong for silica dust or too weak for wood chips. Each material gathered needs to have the velocity and volume of air tailored to its needs.

In this case, silica dust could use a lower horsepower fan or adjust the ducting diameter to provide less velocity. The operation creating excess wood chips would use a higher horsepower fan to suck up the material or adjust the ducting diameter to provide more velocity. On both of the applications, the hood would be tailored to the operation size to capture the appropriate amount of dust.

Adjusting the dust pickup hood size and shape changes the volume of air intake while the ducting diameter and fan's horsepower adjusts the velocity to create the most effective industrial dust collector possible.

The duct system itself needs to be designed to keep consistent airflow with the appropriate velocity. If the velocity in the ducting is too low, the material can stop in the ducting, not making it to the separation device a.k.a. the proper dust collector. If the velocity is too high, the incoming material can cause wear to the ducting through abrasion. Proper sizing and layout helps extend the lifespan of the dust collector's ducting.

Nailing the proper amount of velocity and air used to collect dust is essential for industrial dust collection design.

PROS AND CONS TO INDUSTRIAL DUST COLLECTORS

It's important to implement the best dust control solution for each unique scenario. Weighing the options is always a smart choice, so here's a list on the advantages and disadvantages of industrial dust collectors.

PROS

- Conveyor Applicable

- Wetting conveyor belts is not desirable.

- Water-less Dust Suppression

- Applicable to water-excluding operations.

- Effective Method of Dust Control

- Set up properly, industrial dust collectors collect most of the generated particles.

- Customization

- Can be the exact size and shape to fit your needs.

- Excellent Indoor Application

- Designed to keep areas clear of indoor fugitive dust.

CONS

- High Maintenance/Dust Collection Dumping

- Separation devices on systems often need reoccurring dumping of collected materials.

- Expensive Dust Control

- The larger and more customized the collector gets the more expensive the system becomes.

- Systems can become as expensive as millions of dollars.

- Large Systems

- Can take up lots of valuable space inside facilities or on outside land.

Industrial dust collectors have a unique set up in the dust control industry, backed by lots of customization and indoor specialty. The systems are an excellent way to keep workers safe and the environment free of fugitive dust if you can afford the proper set-up and handle the reoccurring maintenance.

REFERENCES

Dust Collection System Information - https://airhand.com/designing/

How do Industrial Dust Collectors Work? - https://cpef.com/blog/how-do-industrial-dust-collectors-work/

Industrial Dust Collector System Components - https://www.us-duct.com/special-duct-fabrications/industrial-dust-collection-systems

SUBSCRIBE TO BOSSTEK FOR MORE INFORMATION!

Receive more information in the future on BossTek® blogs and products.