New U.S. EPA coal ash disposal rules will likely close remaining surface impounds due to noncompliance and the cost of retrofit.

When it comes to fly ash, it is clear that the U.S. EPA prefers – and is steering operators toward—dry storage.

The EPA’s proposed final rule on coal ash disposal regulates groundwater contamination, leachate control, and structural containment of fly ash storage for the first time in response to recent surface impound leaks.

The EPA says Coal Combustion Residuals (CCR) require ’cradle-to-grave’ management and that storage ponds carry a “potential for loss of life, environmental damage, and economic loss”.

Even if the rules are still under review, the industry needs to start planning its inevitable shift away from pond storage. The future is clearly in dry storage with a proactive dust and runoff control plan.

Stockpile and Landfill Dust Control

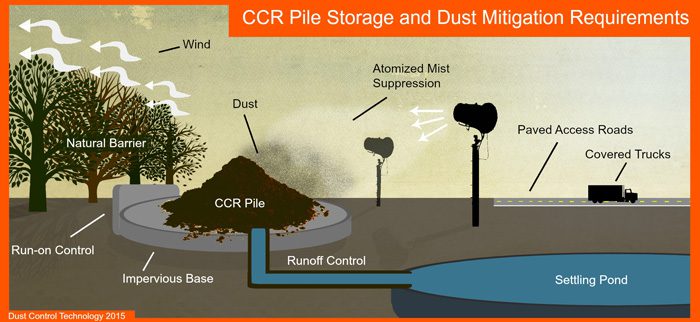

The EPA identifies two forms of dry storage: CCR pile and landfill.

CCR piles differ from landfills because they are, as the EPA defines, ‘containerized’. ‘Containerized’ doesn’t necessarily mean enclosed, but rather just includes measures to prevent exposure to environment, such as through an impervious base, leachate and runoff collection, or wind barriers.

The EPA will be looking to see if operations are implementing quality fugitive dust plans that would be expected to reduce fugitive dust to appropriate levels.

Suggested measures include:

- Paving and sweeping roads, using covered trucks for transport, and reducing traffic speed.

- Short of enclosing the CCR pile, operations can use barriers, such as a tree line, to reduce wind velocity. It is also recommended that operations halt activity in high wind conditions.

- Misting system

Storm Water Runoff Management

You can’t separate your dust suppression and storm water runoff plans. Operators must continue to develop a drainage system accounting for the calculated expected runoff while considering topography and runoff patterns.

The EPA doesn’t see normal runoff from the pile or the low water volume produced by atomized mist to carry enough CCR to be considered CCR storage. Therefore, settling ponds for drainage are not subject to the strict rules governing surface impounds.

Simply put, reducing your dust suppression water usage will lower runoff. And atomized mist uses more than 20 times less water than industrial sprinklers.

In addition to that and the reduced cost in water, savings can be achieved through greater overall efficiency of the operation.

There is a proper balance of moisture level that prevents the ash from drying out and creating dust that could migrate off-site, but also not getting the material too wet. In addition to the runoff concerns, coal ash turns into a sticky muck when oversaturated. This muck is hard on equipment and difficult to handle.

Airborne Dust Suppression

Atomizing nozzles fracture the incoming stream into millions of tiny water droplets — just the right size to collide with airborne dust and bring it to the ground.

A dust particle that is smaller than the water droplet has a tendency to get trapped in the drop's surrounding air stream rather than colliding. It takes a mist to bring down floating dust particles.

Fly ash is also considered hydrophobic, which means it is seemingly repelled by water. Fly ash can benefit from a surfactant, which lowers the surface tension of the water droplet, making airborne capture more effective.

Implement Dust Control Today!

Receive a FREE quote and talk to a dust control specialist today to stop fugitive dust!

Get A Quote

More BossTek

Subscribe and Stay Up-to-Date!

Receive a monthly newsletter keeping you up-to-date on the latest in dust and odor control.

Subscribe