Every dust control plan uses water because it is inexpensive, easy to obtain, and safe for the environment.

Except when it isn’t.

Debilitating droughts are currently swallowing many areas of the world. In South America, the government of Brazil is advising citizens to prepare for the worst as they endure what is being called the most severe drought in their history.

In the United States, the State of California faces yet another year of intense drought and operators are forced to navigate through often conflicting air pollution and water conservation directives. And as rushing through showers, allowing lawns to go brown, and entertaining thoughts of drinking recycled sewage water are among the least of citizen’s concerns, they see industry appearing to dump drinkable water on dirt.

Suddenly, the neighbors whom operators sought to protect from dust emissions are taking a closer look at dust suppression methods. Even the use of recycled water cannot settle the controversy due to additional pollution concerns.

Drought not only forces water conservation, but makes dust more of a problem. There is no silver bullet for this heated issue. However, some methods of suppression use more water than others and that could amount to millions of gallons saved.

Atomized Mist Dust Control

For decades, dust suppression meant industrial sprinklers or a person standing around holding a fire hose.

One is made for irrigation and the other putting out fires.

And they are really good at what they were designed to do: providing maximum water flow.

Both methods can wet surfaces to prevent dust, but they use a lot more water than is necessary. And their water droplet size is too large to capture airborne dust.

You can set out to save money and end up spending more in the long run. Even in times of adequate rainfall, less is always more.

For decades, dust suppression meant industrial sprinklers or a person standing around holding a fire hose.

One is made for irrigation and the other putting out fires.

And they are really good at what they were designed to do: providing maximum water flow.

Both methods can wet surfaces to prevent dust, but they use a lot more water than is necessary. And their water droplet size is too large to capture airborne dust.

You can set out to save money and end up spending more in the long run. Even in times of adequate rainfall, less is always more.

Less water means:

- More strategic water usage and lower associated cost.

- Reduced storm water effects and runoff, critical in keeping air and land pollution in balance.

- Fewer pools of water to ensure a safer and more efficient worksite.

- Avoided product oversaturation, often creating a muck that is difficult to handle and sticks to facility surfaces and equipment, shortening the life of both.

Atomized mist dust cannons were developed specifically with dust suppression in mind, using just the amount of water that is necessary to wet surfaces and bring airborne dust particles to the ground.

Saving Water in Dust Control Management

To illustrate this, let’s compare atomized mist to the other two methods, as well as a heavy rainstorm to add a familiar perspective.

All methods can be adjusted to give different output based on need.

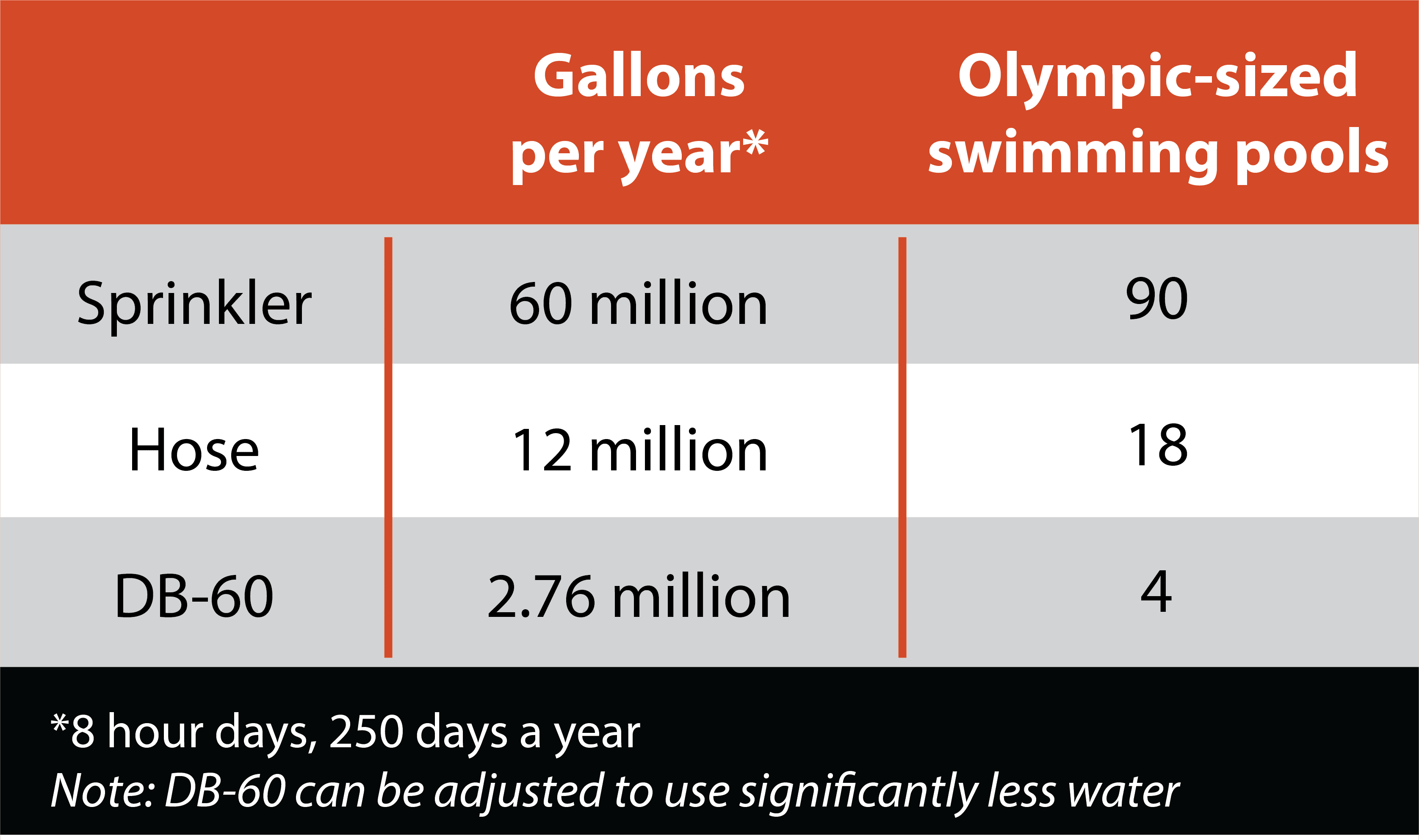

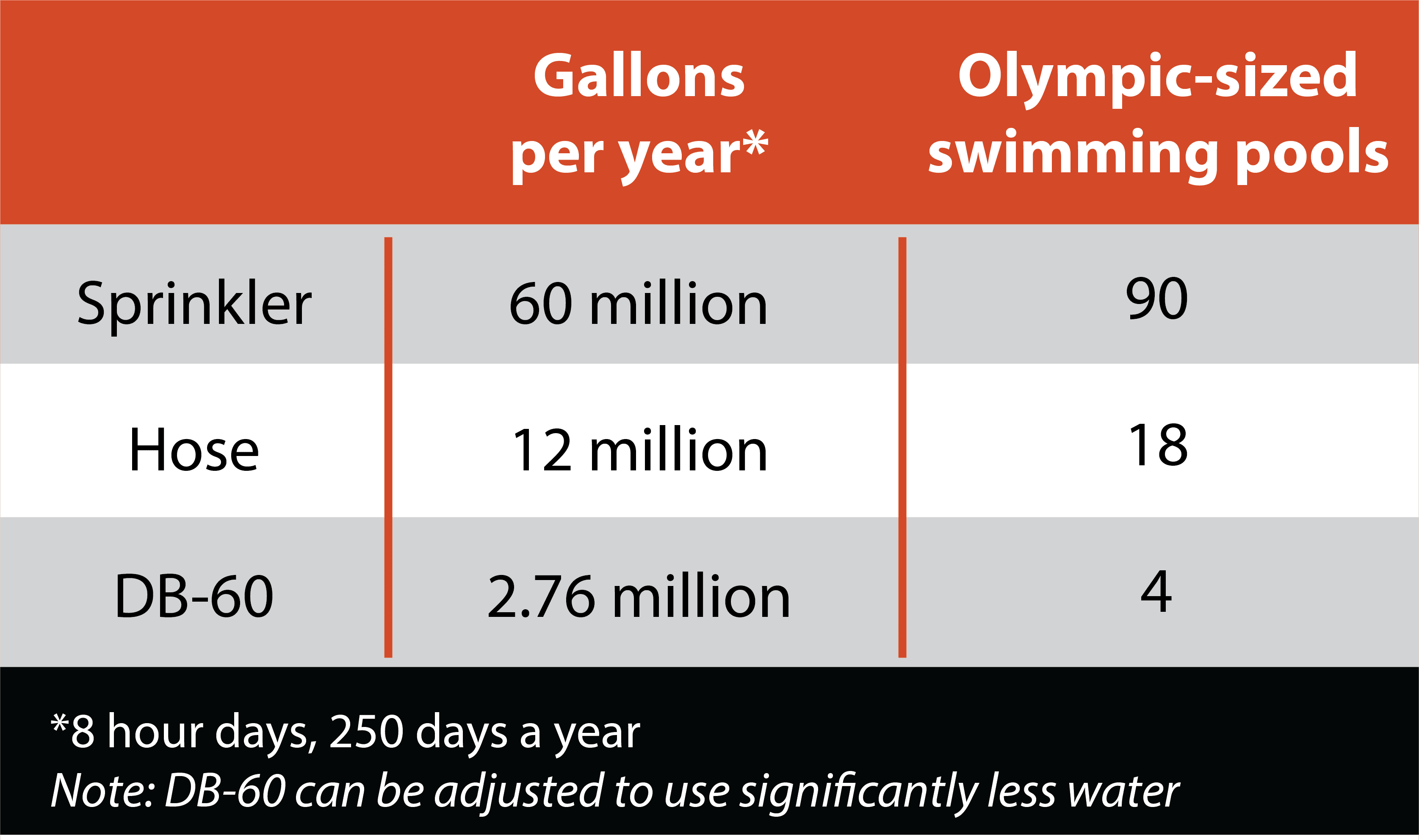

For this comparison, we’ll use the popular DustBoss DB-60 mist cannon, named so because the range is 60 meters (200 feet). We are comparing this to a sprinkler model with similar coverage area and a 1.5 inch fire hose, which is the size that feeds the DB-60.

This industrial sprinkler can run about 500 GPM (1,893 LPM), making it the worst in terms of water usage. That is more than 21 times more water than the DB-60 at 23 GPM (88 LPM).

The fire hose works at 100 gallons per minute (GPM) (378 LPM), more than four times more water than the DB-60.

Conserving with Dust Control Surfactants

Surfactants can be metered into atomized mist using a dosing pump, increasing the water’s potency against fugitive dust and stretching out water usage even further.

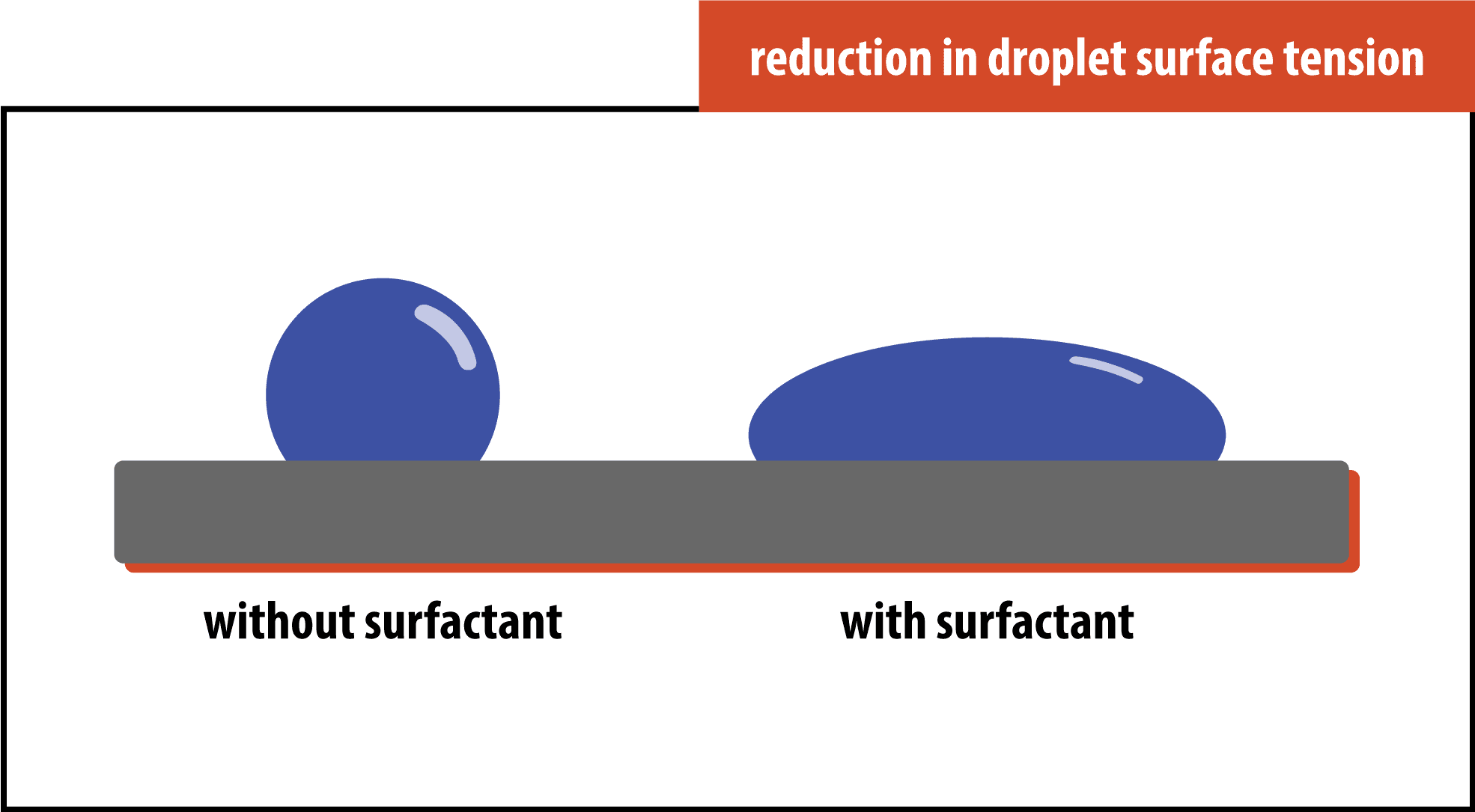

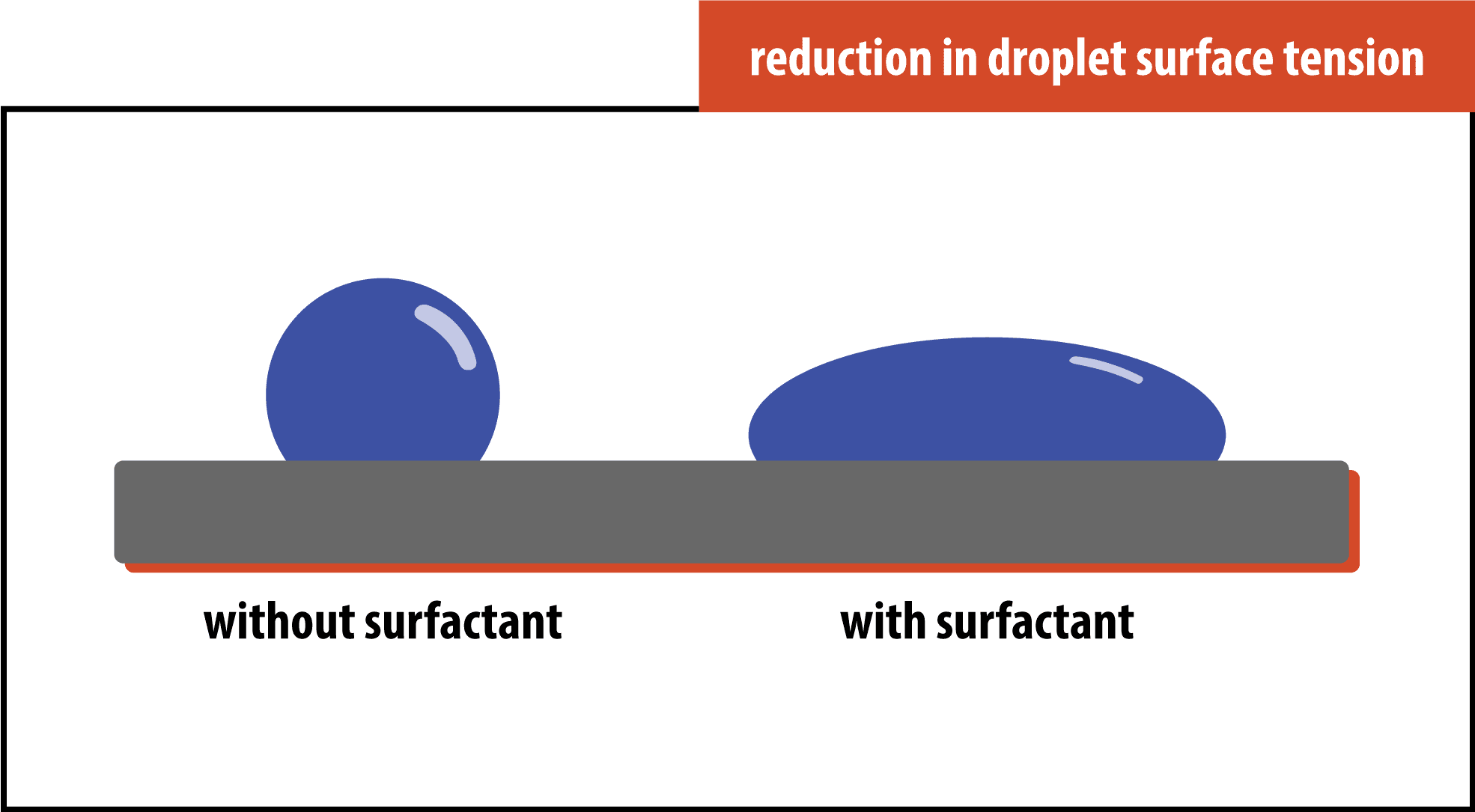

Surfactants, short for surface-acting agents, can be added to the water to improve the wetting characteristics of water. We often say it makes the water wetter, making it easier for the droplet to collide with the dust particle by lowering the drop’s surface tensions.

Think about water on a smooth surface, such as raindrops on a window. Water on a smooth surface will usually form a bead with strong walls. That is surface tensions that prevents the walls from collapsing.

Water treated with surfactants create a flatter bead. Weaker surface tensions mean weaker walls, less able to support a structure. And weaker walls mean more collisions. Surfactants just make water more effective at airborne suppression.

Surfactants can help make a smaller amount of water go further, but as with any chemicals or additives, you always need to pay special attention to the environmental impact and runoff – and impact to product.

Get a FREE site analysis and plan for dust control today!

Talk to a dust control specialist today and analyze your jobsite to create a power dust control plan today!

Free Site Analysis

[formidable id=17 title=true description=true]

More BossTek

Subscribe and Stay Up-to-Date!

Receive a monthly newsletter keeping you up-to-date on the latest in dust and odor control.

Subscribe